Chemical machinery and equipment need to withstand certain chemical erosion and high-temperature and high-pressure environments, so they need to be manufactured with high-quality, corrosion-resistant materials. Stainless steel materials play an important role in the manufacturing of chemical machinery and equipment because of their reliable corrosion resistance and high strength.

Stainless steel can be widely used in various types of chemical equipment. These include:

1. Storage tanks and reactors: Storage tanks and reactors are important equipment needed in chemical production. This equipment requires the use of corrosion-resistant materials to ensure longevity and productivity. Stainless steel materials are widely used in these devices because of their reliable corrosion resistance and strength.

2. Reactor: A stainless steel reactor has good resistance to acid, alkali, high temperature, etc., and can be used for a variety of chemical reactions.

3. Conveying equipment: Conveying equipment is another important equipment category in chemical production. This equipment requires corrosion-resistant materials to ensure a smooth conveyance of production materials. The corrosion resistance of stainless steel makes it an ideal choice for manufacturing conveyor equipment.

4. Pipes: Stainless steel pipes have the advantages of low friction coefficient and strong corrosion resistance, and are suitable for pipeline systems in chemical medium transportation and chemical reaction processes.

5. Heat exchanger: A stainless steel heat exchanger has the advantages of high heat transfer efficiency, corrosion resistance, easy cleaning, etc., and is suitable for the heat exchange process in chemical production.

6. Environmental protection equipment: Stainless steel pipes play an important role in chemical environmental protection equipment. For example, flue gas desulfurization equipment, wastewater treatment equipment, sewage treatment equipment, etc., often use corrosion-resistant stainless steel pipes to treat harmful gases, wastewater and sewage, etc.

Principles for selecting stainless steel materials for chemical equipment

Generally speaking, the stainless steel chemical equipment pipe materials used in the chemical and petroleum industries are 304, 316, 321, etc. When choosing stainless steel materials, you generally need to consider the following aspects:

1. Medium properties: Different media have different material requirements for stainless steel chemical equipment pipe, and corresponding stainless steel materials need to be selected.

2. Working environment: Stainless steel materials will face different mechanical and chemical corrosion in different working environments, so it is necessary to choose a suitable stainless steel material.

3. Production cost: Different stainless steel materials have different production costs, and economy and quality need to be considered comprehensively.

Stainless steel material has high stability. The chemicals used in the chemical production process have various ingredients and are highly corrosive, but a dense passivation film is formed on the surface of stainless steel, which effectively prevents corrosion and oxidation. Therefore, chemical equipment made of stainless steel can maintain a high degree of stability during long-term use.

Stainless steel chemical equipment pipe is increasingly used in the chemical industry. Its performance in production safety, equipment stability, production efficiency and product quality has made it a must-have for chemical companies.

Introduction

| Item | Stainless Steel Chemical Equipment Tube/Pipe | ||||||||||

| Standard | AISI, ASTM, DIN, JIS, GB, ASME, En, GOST | ||||||||||

| Material | 304 304L 304h 316 316L 316h 321 321H 317L 347 347H, ect. | ||||||||||

| Surface | Pickling | ||||||||||

| Shape | Square, Rectangular, Round | ||||||||||

| Type | Cold drawing and cold rolling | ||||||||||

| Processing Service | Bending Welding Decoiling Punching Cuttingmoulding | ||||||||||

| size | Length | 1-12m/Custom | |||||||||

| Outer diameter | OD: 6mm~630mm, WT: 0.3mm~68mm | ||||||||||

| Delivery time | Within 5-30 days after receiving the prepaid | ||||||||||

| Pipe Ends | Plain end/Beveled,protected by plastic caps on both ends, cut quare,grooved,threaded and coupling,etc. | ||||||||||

| Package | PVC Bag + Nylon Belt + Cable Tie or as Request | ||||||||||

Production process.jpg)

Size of stainless steel pipe

Xinhang Special Material Co., Ltd. Hangzhou Branch is famous China 304 High Stability Chemical Equipment Stainless Seamless Steel Tubing suppliers and OEM/ODM 304 High Stability Chemical Equipment Stainless Seamless Steel Tubing manufacturers, founded in 2007 and moved to Longyou Economic Development Zone, Zhejiang Province, in 2022. It covers an area of 130,000 square meters, more than 30 production lines, 300 workers, 20 R&D people, 30 inspection people and an annual output of 50,000 tons.

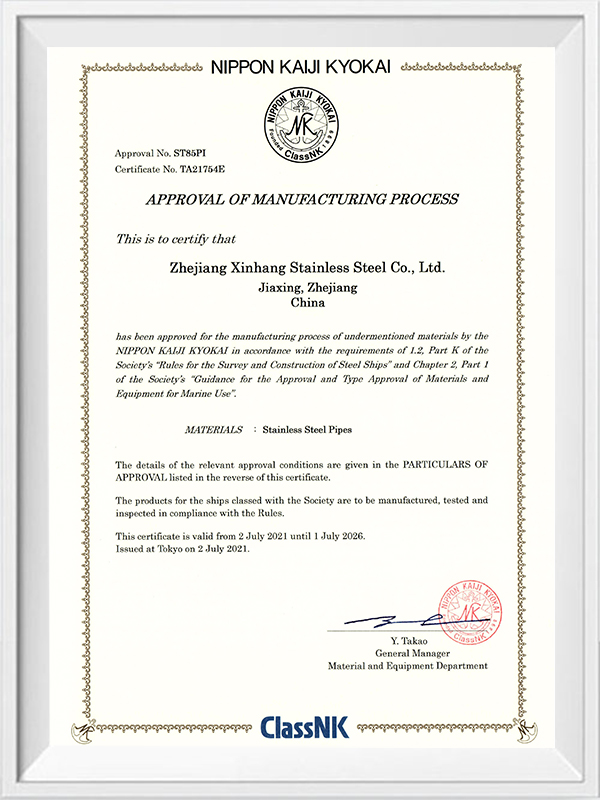

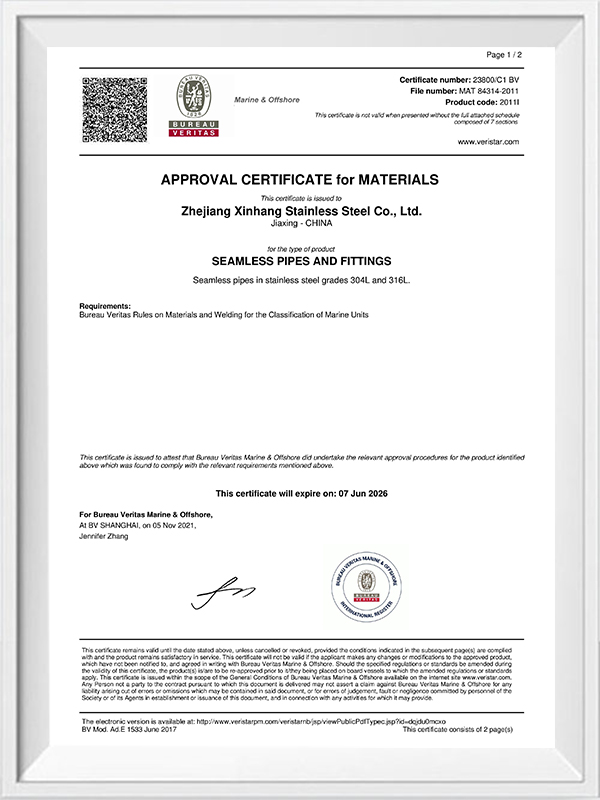

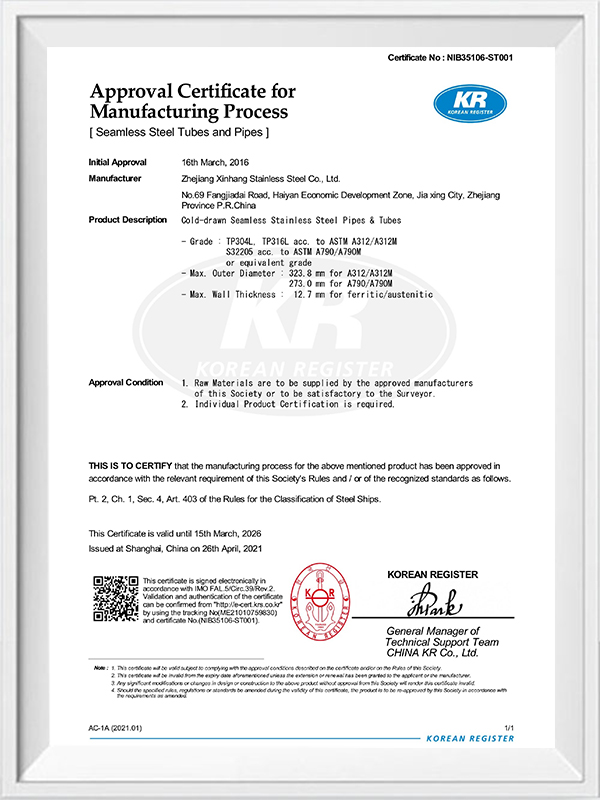

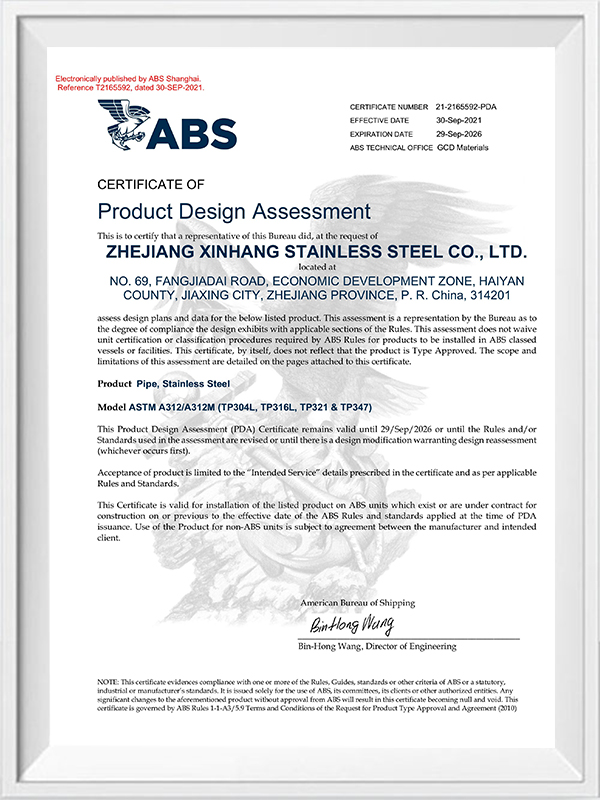

It has passed ISO9001:2008 quality management system, PED 97/23/EC EU Pressure Equipment Directive certification, China Special Equipment Manufacturing License (Pressure Tube) TS certification, ASME certification, provincial enterprise standardization management system, ISO14000:2004 environment management system, cleaner production (green enterprise), and a series of certifications, as well as China Classification Society (CCS), American Bureau of Shipping (ABS), British Register of Shipping (LR), Deutsche Veritas (GL), Bureau Veritas Society (BV), Det Norske Veritas (DNV), and Korean Register of Shipping (KR) factory certification.

The main products include stainless steel pipes, pipe fittings, flanges, valves, etc., which are widely used in petroleum, chemical industry, nuclear industry, smelting, shipbuilding, pharmaceuticals, food, water conservancy, electric power, new energy, mechanical equipment, and other fields. The company adheres to the corporate tenet of "quality for survival, reputation for development" and wholeheartedly serves every customer to create a win-win situation.

Best way to seal stainless steel pipe threads with tape For stainless steel NPT threads, use a high-density PTFE stainless steel pipe tape and apply 3–5 tight wraps in the direction of tightening, ke...

View MoreUnderstanding Thread Types for Stainless Steel Pipe Threading stainless steel pipe requires selecting the appropriate thread standard based on your application. NPT (National Pipe Taper) and BSP (Bri...

View MoreWhat Are Stainless Steel Pipe Supports and Why They Matter Stainless steel pipe supports are structural components designed to secure, stabilize, and distribute the weight of piping systems while res...

View MoreWe'll never share your email address and you

can opt out at any time, we promise.