In the power industry, stainless steel pipes are widely used due to their reliable corrosion resistance, high-temperature resistance, and mechanical properties. These pipelines are used to transport various fluid media, such as cooling water, steam, chemical reagents, etc., to meet the operational needs of power equipment.

Thermal power generation is the use of coal combustion heat energy to heat water, so that water into high-pressure steam, and then by the steam to drive a generator and then generate electricity as a way of power generation. The thermal power station is mainly composed of a power generation boiler, steam turbine, and generator. The steam and water pipes in power generation boilers include reheating pipes, superthermal pipes, water wall pipes, economizer pipes, air preheating pipes, heat conduction pipes, drop pipes, and various combination box pipes.

Because the use of the above pipelines is under high temperature and high-pressure conditions for a long time, the pipelines will undergo oxidation and corrosion under the action of high-temperature flue gas and water vapor, so the steel pipes are required to have high-lasting strength, high oxidation and corrosion resistance and good structural stability. In order to meet the above requirements, stainless steel pipes are widely used in thermal power boilers.

The main applications of stainless steel pipes in the power industry include:

1. Conveying cooling water: used in the cooling system of generator sets, transformers, and other equipment.

2. Conveying steam: steam systems for steam turbines, boilers, and other thermal equipment.

3. Conveying chemical reagents: used in chemical water treatment, wastewater treatment, and other systems.

Nuclear grade pipes in nuclear power plants: used for transporting radioactive media and high temperature and high-pressure water.

Special requirements for stainless steel electrical pipes in the power industry include:

1. Corrosion resistance: A stainlesssteel electrical pipe can resist the erosion of various corrosive media to ensure the long-term stable operation of the pipeline.

2. High-temperature resistance: can maintain good mechanical properties and stability in high-temperature environments.

3. Sealing: Ensure that there is no leakage at the pipe connection and prevent media leakage from causing security risks.

4. Cleanliness: For some special applications, such as nuclear-grade piping in nuclear power plants, an extremely high degree of cleanliness is required inside the piping.

Introduction

| Item | Stainless Steel Electrical ConduitTube/Pipe | ||||||||||

| Standard | ASTM, ASME,EN, JIS, DIN,GB/T etc | ||||||||||

| Material | 1000 Series, 2000 Series, 3000 Series etc | ||||||||||

| Surface | NO.1, 2D, 2B, BA (Bright Annealed), NO.3, NO.4, HL (Hair Line), NO.7, NO.8, SATIN. | ||||||||||

| Shape | Round, Square, Oval, Flat Oval, Hexagon, Octagon | ||||||||||

| Type | Cold drawing & cold rolling | ||||||||||

| Processing Service | Cutting, Bending, Threading, Welding, Grooving, Coating, Drilling, Galvanizing, Heat Treatment, Punching. | ||||||||||

| size | Length | 3.75m or as required | |||||||||

| Outer diameter | OD: 12.7mm~630mm WT: 1mm~50mm | ||||||||||

| Delivery time | Within 5-30 days after receiving the prepaid | ||||||||||

| Package | Standard export seaworthy package,or as required | ||||||||||

Production process.jpg)

Rigid Stainless Steel Conduit Specification

| Trade Size | Metric Designator | Nominal | Outside | Nominal Wall | Thickness | Approx. Wt. | Per 100FT.(30.5M) |

| in. | mm | in. | mm | lb. | kg | ||

| 1/2 | 16 | 0.84 | 21.3 | 0.104 | 2.6 | 82 | 37.2 |

| 3/4 | 21 | 1.05 | 26.7 | 0.107 | 2.7 | 109 | 49.4 |

| 1 | 27 | 1.315 | 33.4 | 0.126 | 3.2 | 161 | 73.0 |

| 1-1/4 | 35 | 1.66 | 42.2 | 0.133 | 3.4 | 218 | 98.9 |

| 1-1/2 | 41 | 1.9 | 48.3 | 0.138 | 3.5 | 263 | 119.3 |

| 2 | 53 | 2.375 | 60.3 | 0.146 | 3.7 | 350 | 158.7 |

| 2-1/2 | 63 | 2.857 | 73 | 0.193 | 4.9 | 559 | 253.5 |

| 3 | 78 | 3.5 | 88.9 | 0.205 | 5.2 | 727 | 329.7 |

| 3-1/2 | 91 | 4 | 101.6 | 0.215 | 5.5 | 880 | 399.1 |

| 4 | 103 | 4.5 | 114.3 | 0.225 | 5.7 | 1030 | 467.1 |

| 5 | 129 | 5.563 | 141.3 | 0.245 | 6.2 | 1400 | 634.9 |

| 6 | 155 | 6.625 | 168.3 | 0.266 | 6.8 | 1840 | 834.5 |

Xinhang Special Material Co., Ltd. Hangzhou Branch is famous China Seamless 114 Ss High Temperature Resistance Duplex Electrical Pipe Manufacturers suppliers and OEM/ODM Seamless 114 Ss High Temperature Resistance Duplex Electrical Pipe Manufacturers manufacturers, founded in 2007 and moved to Longyou Economic Development Zone, Zhejiang Province, in 2022. It covers an area of 130,000 square meters, more than 30 production lines, 300 workers, 20 R&D people, 30 inspection people and an annual output of 50,000 tons.

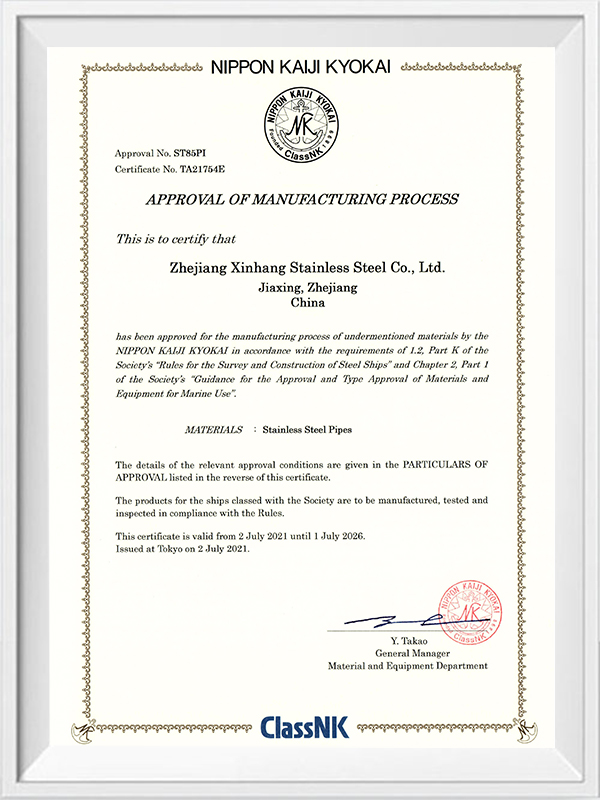

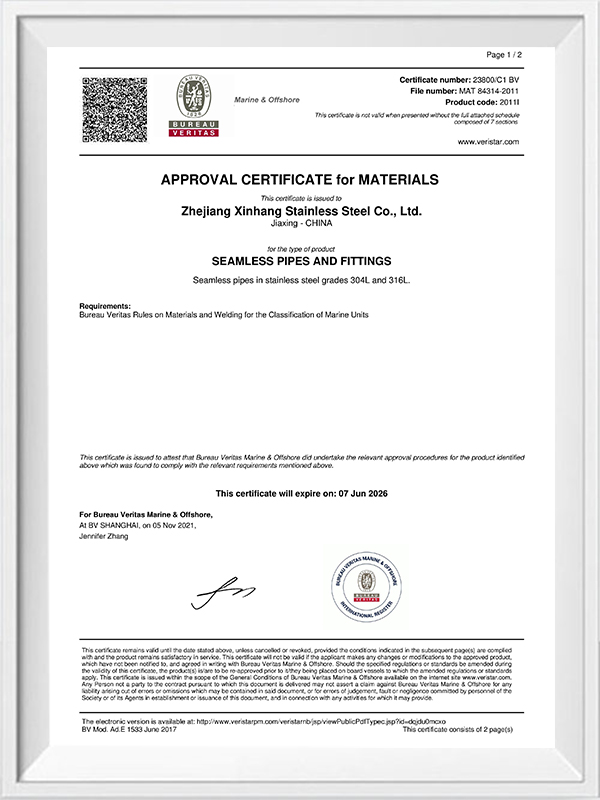

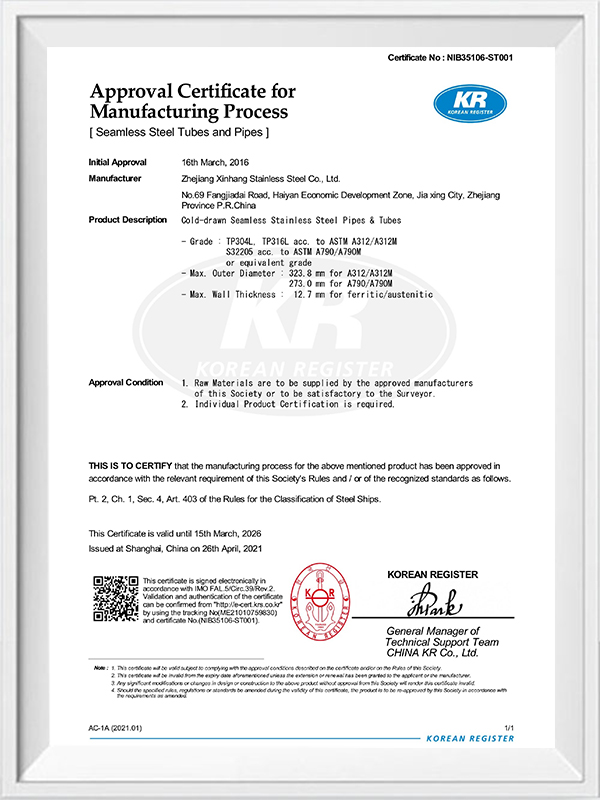

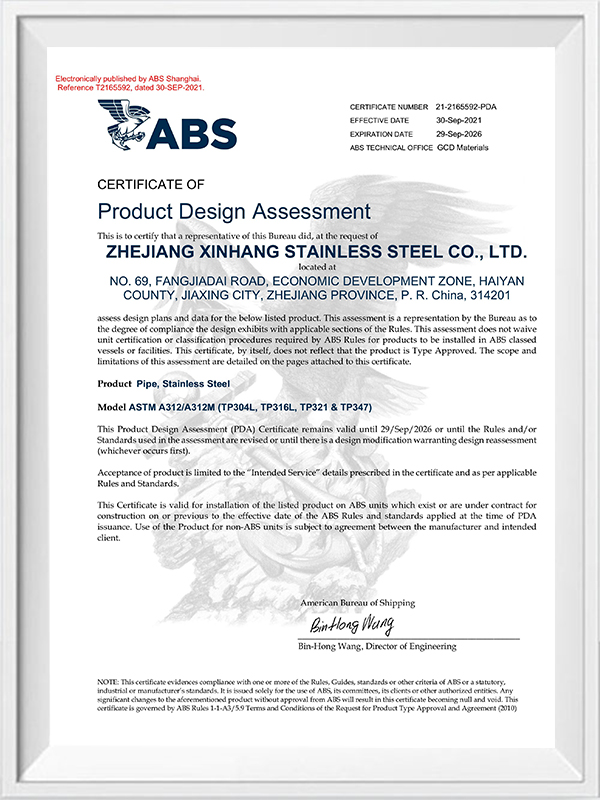

It has passed ISO9001:2008 quality management system, PED 97/23/EC EU Pressure Equipment Directive certification, China Special Equipment Manufacturing License (Pressure Tube) TS certification, ASME certification, provincial enterprise standardization management system, ISO14000:2004 environment management system, cleaner production (green enterprise), and a series of certifications, as well as China Classification Society (CCS), American Bureau of Shipping (ABS), British Register of Shipping (LR), Deutsche Veritas (GL), Bureau Veritas Society (BV), Det Norske Veritas (DNV), and Korean Register of Shipping (KR) factory certification.

The main products include stainless steel pipes, pipe fittings, flanges, valves, etc., which are widely used in petroleum, chemical industry, nuclear industry, smelting, shipbuilding, pharmaceuticals, food, water conservancy, electric power, new energy, mechanical equipment, and other fields. The company adheres to the corporate tenet of "quality for survival, reputation for development" and wholeheartedly serves every customer to create a win-win situation.

Essential Setup for TIG Welding Stainless Steel Pipe TIG welding stainless steel pipe is unforgiving of contamination and excess heat. A repeatable setup starts with stable power delivery, consistent...

View More“Corten” is a common market name for weathering steel—low-alloy structural steels engineered to form a protective oxide “patina” in the right exposure conditions. This article focuses on corten steel ...

View MoreIntroduction to Alloy Steel Alloy steel is a type of steel that is made by combining carbon steel with various alloying elements such as chromium, nickel, molybdenum, and vanadium. These alloying elem...

View MoreWe'll never share your email address and you

can opt out at any time, we promise.