A stainless steel heat exchanger tube is a high-performance heat exchanger material. Due to its corrosion resistance, high-temperature strength, and reliable mechanical properties, it is used in various chemical, pharmaceutical, food, aerospace, energy, and other fields. Heat exchange equipment is also used in more and more fields.

The working principle of stainless steel heat exchanger tubes is to use the heat conduction of the fluid in the pipe to transfer heat between the heat source and the cold source. Specifically, when the temperature of the fluid in the tube is high, heat is transferred to the cold source outside the tube through the tube wall, causing the temperature of the cold source outside the tube to increase; conversely, when the temperature of the fluid in the tube is low, heat is transferred from the heat source outside the tube to The pipe wall reduces the temperature of the heat source outside the pipe. This heat transfer process is mainly achieved through two methods: conduction and convection.

The heat exchange tube is one of the components of the heat exchanger. It is placed inside the cylinder and is used to exchange heat between two media. Has high thermal conductivity and good isothermal properties. It is a device that can quickly transfer heat energy from one point to another with almost no heat loss, so it is called a heat transfer superconductor, and its thermal conductivity is thousands of times that of copper.

The standard tube lengths of heat exchange tubes are 1.5, 2.0, 3.0, 4.5, 6.0, 9.0m, etc. The use of small pipe diameters can increase the heat transfer area per unit volume, compact the structure, reduce metal consumption, and improve the heat transfer coefficient. It is estimated that changing the heat exchange tube of the same diameter heat exchanger from Φ25mm to Φ19mm can increase the heat transfer area by about 40% and save more than 20% of metal. However, small-diameter pipes have large fluid resistance, are inconvenient to clean, and are prone to scaling and blockage.

Stainless steel heat exchange tubes have the following obvious characteristics:

1. Good corrosion resistance: Stainless steel material itself has good corrosion resistance, especially in harsh environments such as high temperature, high pressure, strong acid, and alkali, the corrosion resistance of stainless steel heat exchange tubes is fully reflected.

2. High heat dissipation efficiency: Because the stainless steel heat exchange tube has a thin wall and good thermal conductivity, the heat dissipation efficiency is high.

3. High-temperature strength: Stainless steel materials have high thermal stability and high-temperature strength, and can operate in high-temperature environments for a long time without deformation or melting.

4. Reliable mechanical properties: Stainless steel materials have reliable mechanical properties such as hardness, ductility, and strength, and can meet the use requirements under various complex working conditions.

5. Easy to process and maintain: Stainless steel heat exchange tubes have high surface smoothness, are easy to clean and maintain, and can extend their service life.

Commonly used materials for heat exchange tubes include carbon steel, low alloy steel, stainless steel, copper, copper-nickel alloy, aluminum alloy, titanium, etc. In addition, there are some non-metallic materials, such as graphite, ceramics, polytetrafluoroethylene, etc. Appropriate materials should be selected during design based on working pressure, temperature, and medium corrosivity.

Introduction

| Item | Stainless Steel Heat Exchanger Tube/Pipe | |

| Standard | GB/T 14976, EN: 10216-5, ASTM A312, DIN17456, DIN17458, JIS G3459 | |

| Material | TP304, TP304L, TP304H, TP316, TP316H, TP316Ti, TP316L, TP321, TP316Mo≥2.5 | |

| Surface | Annealed and pickled, grey white (polished) | |

| Shape | Round Pipe/Tube, U Type Tube | |

| Type | Cold drawing and Cold rolling | |

| Processing Service | Head cutting, Straightening, Cutting, Grinding, Lubrication, Heat treatment, Degreasing | |

| size | Length | 6m or as required |

| Outer diameter | 6m or as required | |

| Delivery time | Within 5-30 days after receiving the prepaid | |

| Package | Standard Sea Export Packaging | |

Production process.jpg)

Mechanical property

| Material Item | 201 | 202 | 304 | 316 |

| Tensile Strength | ≥ 535 | ≥ 520 | ≥ 520 | ≥ 520 |

| Yield Strength | ≥ 245 | ≥ 205 | ≥ 205 | ≥ 205 |

| Extension | ≥ 30% | ≥ 30% | ≥ 35% | ≥ 35% |

| Hardness (HV) | < 253 | < 253 | < 200 | < 200 |

Xinhang Special Material Co., Ltd. Hangzhou Branch is famous China Stainless Seamless Steel Heat Exchanger 304 Pipes Transfer Heat Efficiently suppliers and OEM/ODM Stainless Seamless Steel Heat Exchanger 304 Pipes Transfer Heat Efficiently manufacturers, founded in 2007 and moved to Longyou Economic Development Zone, Zhejiang Province, in 2022. It covers an area of 130,000 square meters, more than 30 production lines, 300 workers, 20 R&D people, 30 inspection people and an annual output of 50,000 tons.

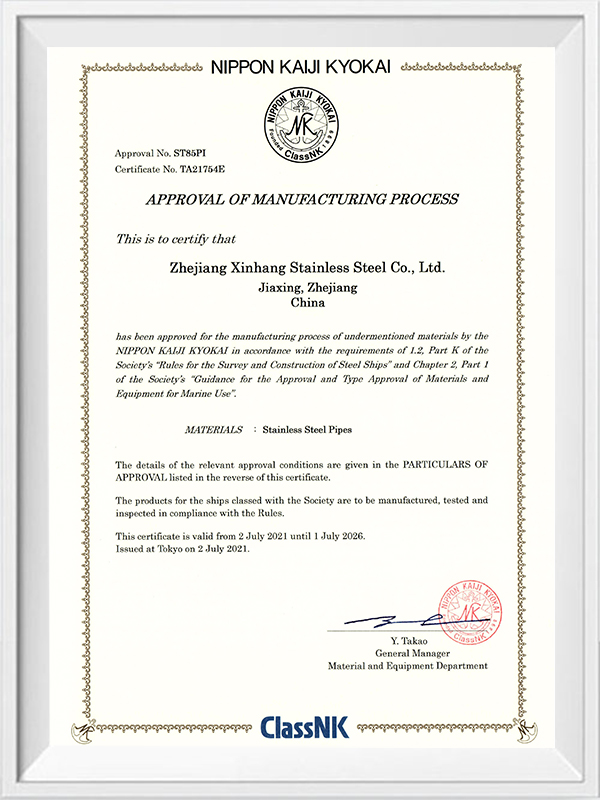

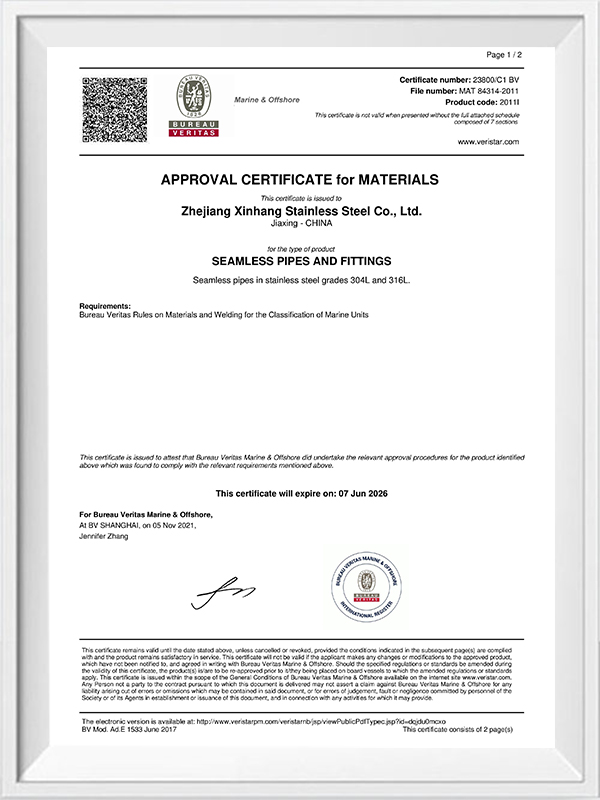

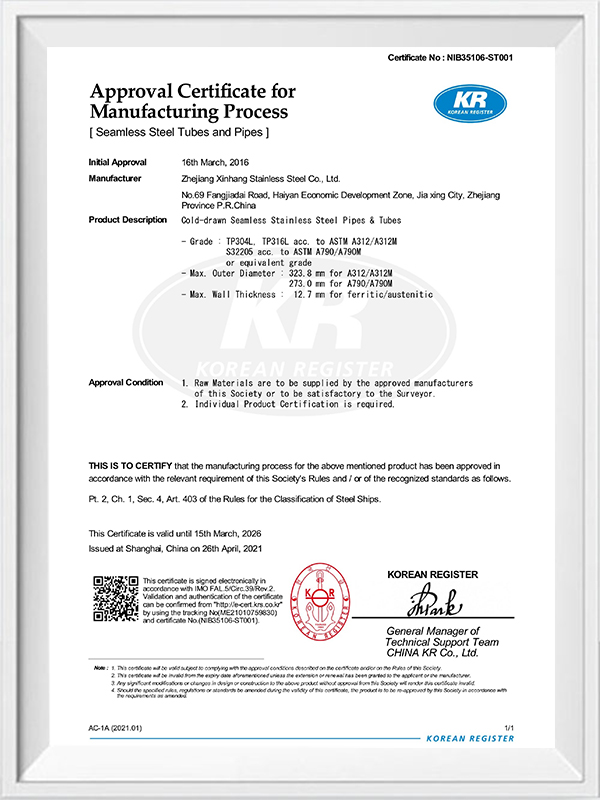

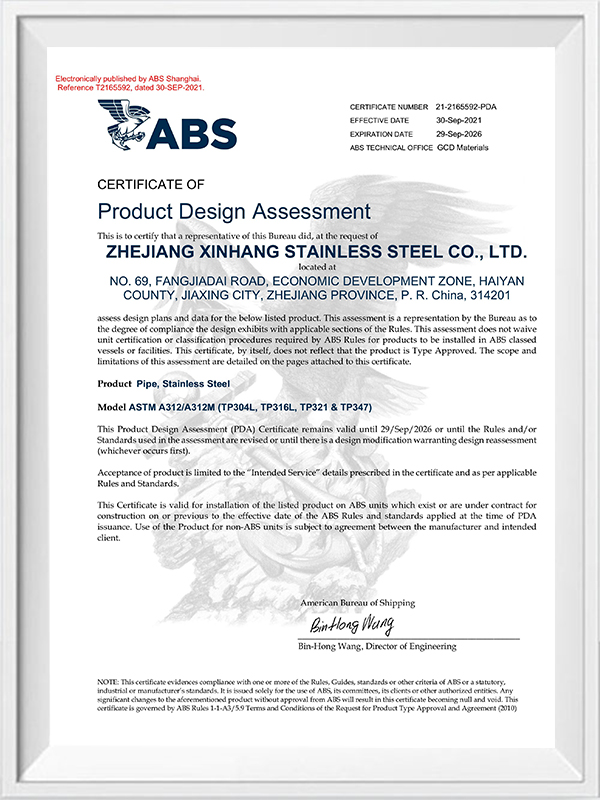

It has passed ISO9001:2008 quality management system, PED 97/23/EC EU Pressure Equipment Directive certification, China Special Equipment Manufacturing License (Pressure Tube) TS certification, ASME certification, provincial enterprise standardization management system, ISO14000:2004 environment management system, cleaner production (green enterprise), and a series of certifications, as well as China Classification Society (CCS), American Bureau of Shipping (ABS), British Register of Shipping (LR), Deutsche Veritas (GL), Bureau Veritas Society (BV), Det Norske Veritas (DNV), and Korean Register of Shipping (KR) factory certification.

The main products include stainless steel pipes, pipe fittings, flanges, valves, etc., which are widely used in petroleum, chemical industry, nuclear industry, smelting, shipbuilding, pharmaceuticals, food, water conservancy, electric power, new energy, mechanical equipment, and other fields. The company adheres to the corporate tenet of "quality for survival, reputation for development" and wholeheartedly serves every customer to create a win-win situation.

What SCH 10 stainless steel pipe specifies (and what it doesn’t) In piping specifications, “SCH” (schedule) is shorthand for wall thickness series, not material grade. For stainless applications, you...

View MoreEssential Setup for TIG Welding Stainless Steel Pipe TIG welding stainless steel pipe is unforgiving of contamination and excess heat. A repeatable setup starts with stable power delivery, consistent...

View More“Corten” is a common market name for weathering steel—low-alloy structural steels engineered to form a protective oxide “patina” in the right exposure conditions. This article focuses on corten steel ...

View MoreWe'll never share your email address and you

can opt out at any time, we promise.