Orifice flanges are one of the economical means of measuring flow. The assemblies and associated components are used for measuring the flow of various Liquids, Gases & Steam from 2” to 32” line sizes.

The traditional orifice flange assembly consists of a pair of flanges, orifice plates, bolts, nuts, gaskets, jacking screws and plugs, etc. The flanges are generally in weld neck design, but it also available slip-on and threaded.

The orifice plate is commonly used as the main element of traffic measurement in the pipeline. Its operating principle is: when the fluid flows from the main pipeline. The orifice plate restricts the flow and develops the Differential Pressure which is proportional to the square root of the flow rate.

The majority of flanges are manufactured from forged steel. The forged construction provides higher strength and durability to provide long-lasting performance in the application.

Introduction

|

Standard |

ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ASME Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ASME B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

|

Material |

Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Low-temperature Steel, Carbon Steel, Cupro Nickel |

|

Surface |

Antirust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized |

|

Type |

Cutting, Heat treatment, Die Forging/Free Forging, CNC Machining |

|

size |

1"-24" |

|

Delivery time |

Within 5-30 days after receiving the prepaid |

|

Packing |

Below 24", will be packed by plywood case; Above 24", will be packed by plywood pallet |

|

Application |

Heavy and light chemicals, Steel, Paper, Nuclear, Petrochemicals, Sewage treatment, Water treatment and distribution, Power Generation, Oil production and refining, Gas Processing and transmission, etc. |

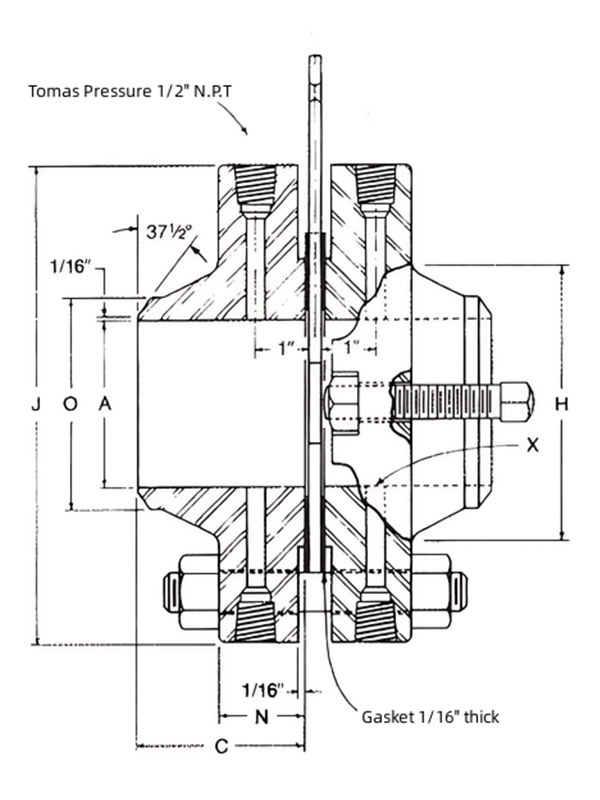

Class 300

|

Size |

Inside diameter and deviation |

Diameter |

Minimal thickness |

Diameter of the Raised face |

Length of the Orifice |

Diameter of the Base |

Shaft diameter At the point of Welding |

Size of Tomas hole |

Flange drilling template |

Screw connector size and length |

Approximate weight (pounds) |

|||

|

inch |

A* |

J |

N* |

C* |

H |

O |

X |

Bolt circulation diameter |

Aperture |

Number of holes |

Size, length, asparagus |

|||

|

½ |

0.622±0.002 |

3 ¾ |

1½ |

1 3/8 |

3 |

1 ½ |

0.84 |

¼ |

2 5/8 |

9/16 |

4 |

½ × 4 3/4 |

½ × 3 |

10 |

|

¾ |

0.824±0.002 |

4 5/8 |

1 ½ |

1 11/16 |

3 1/8 |

1 7/8 |

1.05 |

¼ |

3 ¼ |

11/16 |

4 |

5/8 × 5 |

½ × 3 |

10 |

|

1 |

1.049±0.003 |

4 7/8 |

1 ½ |

2 |

3 ¼ |

2 1/8 |

1.31 |

¼ |

3 ½ |

11/16 |

4 |

5/8 × 5 |

5/8 × 3 |

18 |

|

1½ |

1.610±0.003 |

6 1/8 |

1 ½ |

2 7/8 |

3 3/8 |

2 ¾ |

1.90 |

¼ |

4 ½ |

13/16 |

4 |

¾× 5 ¼ |

5/8 × 3 |

25 |

|

2 |

2.067±0.003 |

6 ½ |

1 ½ |

3 5/8 |

3 3/8 |

3 5/16 |

2.38 |

3/8 |

5 |

11/16 |

8 |

5/8 × 5 |

5/8 × 3 |

27 |

|

2½ |

2.469±0.003 |

7 ½ |

1 ½ |

4 1/8 |

3 ½ |

3 15/16 |

2.88 |

3/8 |

5 7/8 |

13/16 |

8 |

¾ × 5 ¼ |

5/8 × 3 |

35 |

|

3 |

3.068±0.003 |

8 ¼ |

1 ½ |

5 |

3 ½ |

4 5/8 |

3.50 |

3/8 |

6 5/8 |

13/16 |

8 |

¾ × 5 ¼ |

¾ × 3 |

43 |

|

4 |

4.026±0.004 |

10 |

1 ½ |

6 3/16 |

3 5/8 |

5 ¾ |

4.50 |

½ |

7 7/8 |

13/16 |

8 |

¾ × 5 ¼ |

¾ × 3 |

66 |

|

6 |

6.065±0.004 |

12 ½ |

1 ½ |

8 ½ |

3 15/16 |

8 1/8 |

6.63 |

½ |

10 5/8 |

7/8 |

12 |

¾ × 5 ¼ |

¾ × 3 |

106 |

|

8 |

T ± 0.004 |

15 |

1 5/8 |

10 5/8 |

4 3/8 |

10 ¼ |

8.663 |

½ |

13 |

1 |

12 |

7/8 × 5 ¾ |

¾ × 3 |

152 |

|

10 |

T ± 0.005 |

17 ½ |

1 7/8 |

12 ¾ |

4 5/8 |

12 5/8 |

10.75 |

½ |

15 ¼ |

1 1/8 |

16 |

1 × 6 ½ |

1 × 4 ½ |

216 |

|

12 |

T ± 0.005 |

20 ½ |

2 |

15 |

5 1/8 |

14 ¾ |

12.75 |

½ |

17 ¾ |

1 ¼ |

16 |

1 1/8 × 7 ¼ |

1 × 4 ½ |

327 |

|

14 |

T ± 0.005 |

23 |

2 1/8 |

16 ¼ |

5 5/8 |

16 ¾ |

14.00 |

½ |

20 ¼ |

1 ¼ |

20 |

1 1/8 × 7 ½ |

1 × 4 ½ |

448 |

|

16 |

T ± 0.005 |

25 ½ |

2 ¼ |

18 ½ |

5 ¾ |

19 |

16.00 |

½ |

22 ½ |

1 3/8 |

20 |

1 ¼ × 8 |

1 × 4 ½ |

596 |

|

18 |

T ± 0.007 |

28 |

2 3/8 |

21 |

6 ¼ |

21 |

18.00 |

½ |

23 ¾ |

1 3/8 |

24 |

1 ¼ × 8 ¼ |

1 × 4 ½ |

741 |

|

20 |

T ± 0.007 |

30 ½ |

2 ½ |

23 |

6 3/8 |

23 1/8 |

20.00 |

½ |

27 |

1 3/8 |

24 |

1 ¼ × 8 ½ |

1 × 4 ½ |

887 |

|

24 |

T ± 0.007 |

36 |

2 ¾ |

27 ¼ |

6 5/8 |

27 5/8 |

24.00 |

½ |

32 |

1 1/5 |

24 |

1 ¼ × 9 ½ |

1 × 5 ½ |

1311 |

Class 400

|

Size |

Inside diameter and deviation |

Diameter |

Minimal thickness |

Diameter of the Raised face |

Length of the Orifice |

Diameter of the Base |

Shaft diameter At the point of Welding |

Size of Tomas hole |

Flange drilling template |

Screw connector size and length |

Approximate weight (pounds) |

|||

|

inch |

A* |

J |

N* |

C* |

H |

O |

X |

Bolt circulation diameter |

Aperture |

Number of holes |

Size, length, asparagus |

|||

|

4 |

4.026±0.004 |

10 |

1 3/8 |

6 3/16 |

3 ½ |

5 ¾ |

4.50 |

½ |

7 1/8 |

1 |

8 |

7/8 × 5 ¾ |

¾ × 4 |

82 |

|

6 |

6.065±0.004 |

12 ½ |

1 5/8 |

8 ½ |

4 1/16 |

8 1/8 |

6.63 |

½ |

10 5/8 |

1 |

12 |

7/8 × 6 ½ |

¾ × 4 |

136 |

|

8 |

T ± 0.004 |

15 |

1 7/8 |

10 5/8 |

4 5/8 |

10 ¼ |

8.663 |

½ |

13 |

1 1/8 |

12 |

1 × 7 |

¾ ×4 ½ |

213 |

|

10 |

T ± 0.005 |

17 ½ |

2 1/8 |

12 ¾ |

4 7/8 |

12 5/8 |

10.75 |

½ |

15 ¼ |

1 ¼ |

16 |

1 1/8 × 8 |

1 × 4 ½ |

309 |

|

12 |

T ± 0.005 |

20 ½ |

2 ¼ |

15 |

5 3/8 |

14 ¾ |

12.75 |

½ |

17 ¾ |

1 3/8 |

16 |

1 ¼ × 8 ½ |

1 × 4 ½ |

429 |

|

14 |

T ± 0.005 |

23 |

2 3/8 |

16 ¼ |

5 7/8 |

16 ¾ |

14.00 |

½ |

20 ¼ |

1 3/8 |

20 |

1 ¼ × 8 ¾ |

1 × 4 ½ |

554 |

|

16 |

T ± 0.005 |

25 ½ |

2 ½ |

18 ½ |

6 |

19 |

16.00 |

½ |

22 ½ |

1 ½ |

20 |

1 3/8 × 9 ½ |

1 × 5 ½ |

705 |

|

18 |

T ± 0.007 |

28 |

2 5/8 |

21 |

6 ½ |

21 |

18.00 |

½ |

24 ¾ |

1 ½ |

24 |

1 3/8 × 9 ¾ |

1 × 5 ½ |

863 |

|

20 |

T ± 0.007 |

30 ½ |

2 ¾ |

23 |

6 5/8 |

23 1/8 |

20.00 |

½ |

27 |

1 5/8 |

24 |

1 ½× 10 ¼ |

1 × 5 ½ |

1066 |

|

24 |

T ± 0.007 |

36 |

3 |

27 ¼ |

6 7/8 |

27 5/8 |

24.00 |

½ |

32 |

1 7/8 |

24 |

1 ¾ × 11 ½ |

1 × 6 ½ |

1555 |

Class 600

|

Size |

Inside diameter and deviation |

Diameter |

Minimal thickness |

Diameter of the Raised face |

Length of the Orifice |

Diameter of the Base |

Shaft diameter At the point of Welding |

Size of Tomas hole |

Flange drilling template |

Screw connector size and length |

Approximate weight (pounds) |

|||

|

inch |

A* |

J |

N* |

C* |

H |

O |

X |

Bolt circulation diameter |

Aperture |

Number of holes |

Size, length, asparagus |

|||

|

4 |

4.026±0.004 |

10 ¾ |

1 ½ |

6 3/16 |

4 |

6 |

4.50 |

½ |

8 ½ |

1 |

8 |

7/8 × 6 |

¾ × 4 |

103 |

|

6 |

6.065±0.004 |

14 |

1 7/8 |

8 ½ |

4 5/8 |

8 ¾ |

6.63 |

½ |

11 ½ |

1 1/8 |

12 |

1 × 7 |

¾ × 4 |

195 |

|

8 |

T ± 0.004 |

16 ½ |

2 3/16 |

10 5/8 |

5 ¼ |

10 ¾ |

8.663 |

½ |

13 ¾ |

1 ¼ |

12 |

1 1/8 × 8 |

¾ × 4½ |

278 |

|

10 |

T ± 0.005 |

20 |

2 ½ |

12 ¾ |

6 |

13 ½ |

10.75 |

½ |

17 |

1 3/8 |

16 |

1 ¼ × 8¾ |

1 × 5½ |

454 |

|

12 |

T ± 0.005 |

22 |

2 5/8 |

15 |

6 1/8 |

15 ¾ |

12.75 |

½ |

19 ¼ |

1 3/8 |

20 |

1 ¼ × 9 |

1 × 5½ |

553 |

|

14 |

T ± 0.005 |

23 ¾ |

2 ¾ |

16 ¼ |

6 ½ |

17 |

14.00 |

½ |

20 ¾ |

1 ½ |

20 |

1 3/8 × 9¾ |

1 × 5½ |

815 |

|

16 |

T ± 0.005 |

27 |

3 |

18 ½ |

7 |

19 ½ |

16.00 |

½ |

20 ¾ |

1 5/8 |

20 |

1½ × 10 ½ |

1 × 5½ |

1113 |

|

18 |

T ± 0.007 |

29 ¼ |

3 ¼ |

21 |

7 ¼ |

21 ½ |

18.00 |

½ |

25 ¾ |

1 ¾ |

20 |

1 5/8 ×10 ½ |

1 × 6½ |

1306 |

|

20 |

T ± 0.007 |

32 |

3 ½ |

23 |

7½ |

24 |

20.00 |

½ |

28 ½ |

1 ¾ |

24 |

1 5/8 × 12 |

1 × 6½ |

1622 |

|

24 |

T ± 0.007 |

37 |

4 |

27 ¼ |

8 |

28 ½ |

24.00 |

½ |

33 |

2 |

24 |

1 7/8 × 13¾ |

1 × 8 |

2320 |

Class 900

|

Size |

Inside diameter and deviation |

Diameter |

Minimal thickness |

Diameter of the Raised face |

Length of the Orifice |

Diameter of the Base |

Shaft diameter At the point of Welding |

Size of Tomas hole |

Flange drilling template |

Screw connector size and length |

Approximate weight (pounds) |

|||

|

inch |

A* |

J |

N* |

C* |

H |

O |

X |

Bolt circulation diameter |

Aperture |

Number of holes |

Size, length, asparagus |

|||

|

3 |

T ±0.003 |

9 ½ |

1 ½ |

5 |

4 |

5 |

3.50 |

½ |

7 ½ |

1 |

8 |

7/8 × 6 |

¾ × 4 |

79 |

|

4 |

T ±0.004 |

11 ½ |

1 ¾ |

6 3/16 |

4 ½ |

6 ¼ |

4.50 |

½ |

9 ½ |

1 ¼ |

8 |

1 1/8 ×7 |

¾ × 4 |

129 |

|

6 |

T ±0.004 |

15 |

2 3/16 |

8 ½ |

5 ½ |

9 ¼ |

6063 |

½ |

12 ½ |

1 ½ |

12 |

1 1/8 × 8 |

¾×4 ½ |

263 |

|

8 |

T ± 0.004 |

18 ½ |

2 ½ |

10 5/8 |

6 3/8 |

11 ¾ |

8.63 |

½ |

15 ½ |

1 ½ |

12 |

1 3/8×9 |

1×5 ½ |

445 |

|

10 |

T ± 0.005 |

21 ½ |

2 ¾ |

12 ¾ |

7 ¼ |

14 ½ |

10.75 |

½ |

18 ½ |

1 ½ |

16 |

1 3/8×9 ¾ |

1×5 ½ |

634 |

|

12 |

T ± 0.005 |

24 |

3 1/8 |

15 |

7 7/8 |

16 ½ |

12.75 |

½ |

21 |

1 ½ |

20 |

1 3/8×10½ |

1×5 ½ |

872 |

Class 1500

|

Size |

Inside diameter and deviation |

Diameter |

Minimal thickness |

Diameter of the Raised face |

Length of the Orifice |

Diameter of the Base |

Shaft diameter At the point of Welding |

Size of Tomas hole |

Flange drilling template |

Screw connector size and length |

Approximate weight (pounds) |

|||

|

inch |

A* |

J |

N* |

C* |

H |

O |

X |

Bolt circulation diameter |

Aperture |

Number of holes |

Size, length, asparagus |

|||

|

1 |

T ±0.003 |

5 7/8 |

1 ½ |

2 |

3 ¼ |

2 1/16 |

1.32 |

¼ |

4 |

1 |

4 |

7/8×6 |

5/8×4 |

26 |

|

1½ |

T ±0.003 |

7 |

1 ½ |

2 7/8 |

3 ½ |

4 ¾ |

1.90 |

¼ |

4 7/8 |

1 1/8 |

4 |

1×6 ¼ |

5/8×4 |

45 |

|

2 |

T ±0.003 |

8 ½ |

1 ½ |

3 5/8 |

4 |

4 1/8 |

2.38 |

3/8 |

6 ½ |

1 |

8 |

7/8×6 |

5/8×4 |

65 |

|

2½ |

T ±0.003 |

9 5/8 |

1 5/8 |

4 1/8 |

4 1/8 |

4 7/8 |

2.88 |

3/8 |

7 ½ |

1 1/8 |

8 |

1×6 ½ |

5/8×4 |

98 |

|

3 |

T ±0.003 |

10 ½ |

1 7/8 |

5 |

4 5/8 |

5 ¼ |

3.50 |

3/8 |

8 |

1 ¼ |

8 |

1 1/8×7¼ |

¾×4 |

123 |

|

4 |

T ±0.004 |

12 ¼ |

2 1/8 |

6 3/16 |

4 7/8 |

6 3/8 |

4.50 |

½ |

9 ½ |

1 3/8 |

8 |

1 ¼×8 |

¾×4 ½ |

182 |

|

6 |

T ±0.004 |

15 ¼ |

3 ¼ |

8 ½ |

6 ¾ |

9 |

6.63 |

½ |

12 ½ |

1 ½ |

12 |

1 3/8×10¾ |

¾×5½ |

407 |

|

8 |

T ±0.004 |

19 |

3 5/8 |

10 5/8 |

8 3/8 |

11 ½ |

8.63 |

½ |

15 ½ |

1 ¾ |

12 |

1 5/8×12 |

1×7 |

675 |

|

10 |

T ±0.005 |

23 |

4 ¼ |

12 ¾ |

10 |

14 ½ |

10.75 |

½ |

19 |

2 |

12 |

1 7/8×14 |

1×8 |

1099 |

|

12 |

T ±0.005 |

26 ½ |

4 7/8 |

15 |

11 1/8 |

17¾ |

12.75 |

½ |

22 ½ |

2 1/8 |

16 |

2×15¾ |

1×9 |

1706 |

Class 2500

|

Size |

Inside diameter and deviation |

Diameter |

Minimal thickness |

Diameter of the Raised face |

Length of the Orifice |

Diameter of the Base |

Shaft diameter At the point of Welding |

Size of Tomas hole |

Flange drilling template |

Screw connector size and length |

Approximate weight (pounds) |

|||

|

inch |

A* |

J |

N* |

C* |

H |

O |

X |

Bolt circulation diameter |

Aperture |

Number of holes |

Size, length, asparagus |

|||

|

1 |

T ±0.003 |

6 ¼ |

1 ½ |

2 |

3 5/8 |

2 ¼ |

1.32 |

¼ |

4 ¼ |

1 |

4 |

7/8×6 |

5/8×4 |

26 |

|

1½ |

T ±0.003 |

8 |

1 ¾ |

2 7/8 |

4 3/8 |

3 1/8 |

1.90 |

¼ |

5 ¾ |

1 ¼ |

4 |

1 1/8×7 |

¾×4 |

56 |

|

2 |

T ±0.003 |

9 ¼ |

2 |

3 5/8 |

5 |

3 ¾ |

2.38 |

3/8 |

6 ¾ |

1 1/8 |

8 |

18×7 ¼ |

¾×4 |

84 |

|

2½ |

T ±0.003 |

10 ½ |

2 ¼ |

4 1/8 |

5 5/8 |

4 ½ |

2.88 |

3/8 |

7 ¾ |

1 ¼ |

8 |

1 1/8×8 |

¾×4 ½ |

104 |

|

3 |

T ±0.003 |

12 |

2 5/8 |

5 |

6 5/8 |

5 ¼ |

3.50 |

3/8 |

9 |

1 3/8 |

8 |

1 1/4×9¼ |

¾×5 ½ |

188 |

|

4 |

T ±0.004 |

14 |

3 |

6 3/16 |

7 ½ |

6½ |

4.50 |

½ |

10 ¾ |

1 5/8 |

8 |

1 ½×10½ |

¾×5 ½ |

292 |

|

6 |

T ±0.004 |

19 |

4 ¼ |

8 ½ |

10 ¾ |

9 ¼ |

6.63 |

½ |

14 ½ |

2 1/8 |

8 |

2×14 ¼ |

¾×8 |

756 |

|

8 |

T ±0.004 |

21 ¾ |

5 |

10 5/8 |

12 ½ |

12 |

8.63 |

½ |

17 ¼ |

2 1/8 |

12 |

2×15 ¾ |

1×9 |

1152 |

|

10 |

T ±0.005 |

26 ½ |

6 ½ |

12 ¾ |

16 ½ |

14 ¾ |

10.75 |

½ |

21 ¼ |

2 5/8 |

12 |

2 ½×20 |

1×11 |

2136 |

|

12 |

T ±0.005 |

30 |

7 ¼ |

15 |

18 ¼ |

17 ¼ |

12.75 |

½ |

24 3/8 |

2 7/8 |

12 |

2 ¾×22 |

1×12 |

3216 |

Xinhang Special Material Co., Ltd. Hangzhou Branch is famous China Orifice Flange Assembly Is The Element Of Traffic Measurement In The Pipeline suppliers and OEM/ODM Orifice Flange Assembly Is The Element Of Traffic Measurement In The Pipeline manufacturers, founded in 2007 and moved to Longyou Economic Development Zone, Zhejiang Province, in 2022. It covers an area of 130,000 square meters, more than 30 production lines, 300 workers, 20 R&D people, 30 inspection people and an annual output of 50,000 tons.

It has passed ISO9001:2008 quality management system, PED 97/23/EC EU Pressure Equipment Directive certification, China Special Equipment Manufacturing License (Pressure Tube) TS certification, ASME certification, provincial enterprise standardization management system, ISO14000:2004 environment management system, cleaner production (green enterprise), and a series of certifications, as well as China Classification Society (CCS), American Bureau of Shipping (ABS), British Register of Shipping (LR), Deutsche Veritas (GL), Bureau Veritas Society (BV), Det Norske Veritas (DNV), and Korean Register of Shipping (KR) factory certification.

The main products include stainless steel pipes, pipe fittings, flanges, valves, etc., which are widely used in petroleum, chemical industry, nuclear industry, smelting, shipbuilding, pharmaceuticals, food, water conservancy, electric power, new energy, mechanical equipment, and other fields. The company adheres to the corporate tenet of "quality for survival, reputation for development" and wholeheartedly serves every customer to create a win-win situation.

We'll never share your email address and you

can opt out at any time, we promise.