Plate flanges have a similar shape to slip-on flanges. It is a type of flange that has been cut from a flat piece of metal. They are generally suitable for piping systems where the assembly and disassembly of the pipeline are frequent.

Usually, they have a larger circumference than other types of flanges to resist higher levels of pressure. They can make strong connections between different-sized pipes and withstand severe temperature changes. The circular disk is welded onto the end of a pipe and allows it to be bolted to another pipe. Typically used in fuel and water pipelines, the two flange plates will be bolted together with a gasket in between them The flange plate will have bolt holes all around the perimeter and will be used to create junctions, tees, and joints.

Plate flanges can be made from many different types of metal including carbon steel, stainless steel, and alloy steel, among others. It is used in many industries, such as the oil and gas industry, for connecting pipes and shielding them from external elements.

Introduction

|

Standard |

ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48 |

|

Material Grades |

Stainless Steel, Carbon Steel, Alloy Steel, Cupro Nickel (90/10, 70/30, 66/30/2/2), Hastelloy (C-4, C-22, C276, B-2), Nickel (200 /201), Monel (400 & K500), Inconel (600, 601, 625 & 825), Incolloy (800, 800H), Alloy 20, Duplex Steel, SS 904L, Titanium (1 & 2), etc. |

|

Surface |

Antirust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized |

|

Type |

CNC Machining |

|

size |

1"-12" |

|

Delivery time |

Within 5-30 days after receiving the prepaid |

|

Packing |

Wooden Box |

|

Application |

Piping Systems: Plate flanges are commonly used in piping systems to connect pipes and other fittings. |

|

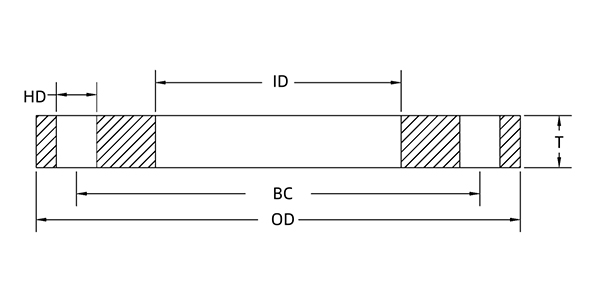

NOMINAL PIPE SIZE |

THICKNESS |

OUTSIDE DIA. (OD) |

INSIDE DIA. (ID) |

NUMBER OF HOLES |

HOLE DIA. |

BOLT CIRCLE |

WEIGHT |

|

In |

T(In) |

OD(In) |

ID(In) |

HOLES |

HD(In) |

BC(In) |

IN POUNDS |

|

1 |

0.500 |

4.25 |

1.063 |

4 |

0.62 |

3.12 |

1.74 |

|

1 ¼ |

0.500 |

4.62 |

1.313 |

4 |

0.62 |

3.50 |

2.01 |

|

1 ½ |

0.500 |

5.00 |

1.563 |

4 |

0.62 |

3.88 |

2.34 |

|

2 |

0.500 |

6.00 |

2.063 |

4 |

0.75 |

4.75 |

3.28 |

|

2 ½ |

0.500 |

7.00 |

2.563 |

4 |

0.75 |

5.50 |

4.52 |

|

3 |

0.500 |

7.50 |

3.063 |

4 |

0.75 |

6.00 |

4.89 |

|

4 |

0.500 |

9.00 |

4.063 |

8 |

0.75 |

7.50 |

6.59 |

|

5 |

0.500 |

10.00 |

5.063 |

8 |

0.88 |

8.50 |

7.32 |

|

6 |

0.500 |

11.00 |

6.063 |

8 |

0.88 |

9.50 |

8.27 |

|

8 |

0.500 |

13.50 |

8.063 |

8 |

0.88 |

11.75 |

11.86 |

|

10 |

0.500 |

16.00 |

10.063 |

12 |

1.00 |

14.25 |

18.39 |

|

12 |

0.500 |

19.00 |

12.063 |

12 |

1.00 |

17.00 |

26.87 |

Xinhang Special Material Co., Ltd. Hangzhou Branch is famous China Stainless Steel Plate Flange Allows To Be Bolted To Another Pipe suppliers and OEM/ODM Stainless Steel Plate Flange Allows To Be Bolted To Another Pipe manufacturers, founded in 2007 and moved to Longyou Economic Development Zone, Zhejiang Province, in 2022. It covers an area of 130,000 square meters, more than 30 production lines, 300 workers, 20 R&D people, 30 inspection people and an annual output of 50,000 tons.

It has passed ISO9001:2008 quality management system, PED 97/23/EC EU Pressure Equipment Directive certification, China Special Equipment Manufacturing License (Pressure Tube) TS certification, ASME certification, provincial enterprise standardization management system, ISO14000:2004 environment management system, cleaner production (green enterprise), and a series of certifications, as well as China Classification Society (CCS), American Bureau of Shipping (ABS), British Register of Shipping (LR), Deutsche Veritas (GL), Bureau Veritas Society (BV), Det Norske Veritas (DNV), and Korean Register of Shipping (KR) factory certification.

The main products include stainless steel pipes, pipe fittings, flanges, valves, etc., which are widely used in petroleum, chemical industry, nuclear industry, smelting, shipbuilding, pharmaceuticals, food, water conservancy, electric power, new energy, mechanical equipment, and other fields. The company adheres to the corporate tenet of "quality for survival, reputation for development" and wholeheartedly serves every customer to create a win-win situation.

We'll never share your email address and you

can opt out at any time, we promise.