The application advantages of 316L stainless steel heat exchange tubes are attributed to the addition of Mo element, which provides corrosion resistance, atmospheric corrosion resistance, and high-temperature strength. This allows for use under harsh conditions.

Additionally, 316 stainless steel exhibits work hardening (non-magnetic), good high-temperature strength, non-magnetism in a solid solution state, and cold rolled products with a pleasing appearance gloss. As a result of these properties, it is widely utilized in heat exchangers within petrochemical, pharmaceutical, food, and other industries.

Based on production process characteristics and appearance attributes, 316 welded stainless steel heat exchange tubes can be categorized into five types.

1. The straight tube heat exchange tube is a commonly used type, known for its simple structure and easy production, making it suitable for all types of heat exchangers.

2. The bellows heat exchange tube features a corrugated surface to increase fluid turbulence and enhance heat exchange efficiency, making it ideal for gas-based shell-side fluid in heat exchangers.

3. Spiral heat exchange tubes have a spiral outer surface to boost fluid turbulence and improve heat exchange efficiency, making them suitable for gas-based shell-side fluid in heat exchangers.

4. Welded heat exchange tubes are connected by welding, offering high strength, sealing performance, and cost advantages. They are suitable for high-temperature and high-pressure heat exchangers.

5. Expansion heat exchange tubes are connected by expansion, providing good sealing performance and easy disassembly. They are suitable for low-temperature and low-pressure heat exchangers.

When choosing the 316L stainless steel heat exchange tube, it is important to consider the following factors:

1. Fluid properties: Select a heat exchange tube with appropriate corrosion and oxidation resistance based on the fluid's characteristics.

2. Working temperature and pressure: Choose a heat exchange tube with suitable strength and stability according to the required working temperature and pressure.

3. Equipment structure and installation requirements: Select the appropriate connection method and manufacturing process of the heat exchange tube type based on equipment structure and installation needs.

In summary, the various types of 316 stainless steel heat exchange tubes include straight, corrugated, spiral, welded, and expansion tubes. When choosing the appropriate type of 316 stainless steel heat exchange tube, it is important to consider factors such as fluid properties, operating temperature and pressure, equipment structure, and installation requirements in order to ensure reliable operation and equipment safety.

Introduction

| Item | Stainless steel tubes for boiler | ||||||||||

| Standard | 1,ASTM A213 EN10217 EN10216-2 2,ASME SA106, ASME SA179, ASME SA192, ASME SA210 3,ASME SA335 4,DIN17175 5,ASME SA209 6,EN10216-2 |

||||||||||

| Material | 1,Austennitic SS (304 316/316L 321 347/347H 904L Alloy254SMO N08031...)Duplex SS, Ni Base Alloy,Ni-Cu Alloy,Hastelloy,T5, T9, T11, T12, T22, T23, T91, T92 2,SA106B, SA106C,SA179,SA192,SA210A1, SA210C 3,P5, P9, P11, P12, P22, P23, P91, P92 4,ST35.8, ST45.8, 15Mo3, 13CrMo44, 10CrMo910, X20CrMoV121 5,T1, T1a, T1b 6,P195GH, P235GH, P265GH, 16Mo3,13CrMo4-5,10CrMo9-10 |

||||||||||

| Surface | Pickling, Bright Tube, Passivation, Polishing | ||||||||||

| End Treatment | Plain End/Bevelled End | ||||||||||

| Type | Welded or Seamless | ||||||||||

| Welding Line Type | ERW, Efw, Seamless, Spiral Welded | ||||||||||

| size | Length | 0.5-12 Meter according to buyer's request | |||||||||

| Outer diameter | OD: 6mm~219mm, WT: 0.5mm~30mm | ||||||||||

| Delivery time | Within 5-30 days after receiving the prepaid | ||||||||||

| Package | Waterproof Paper, Steel Strip Packed and other Standard Export Seaworthy Package, or customized package | ||||||||||

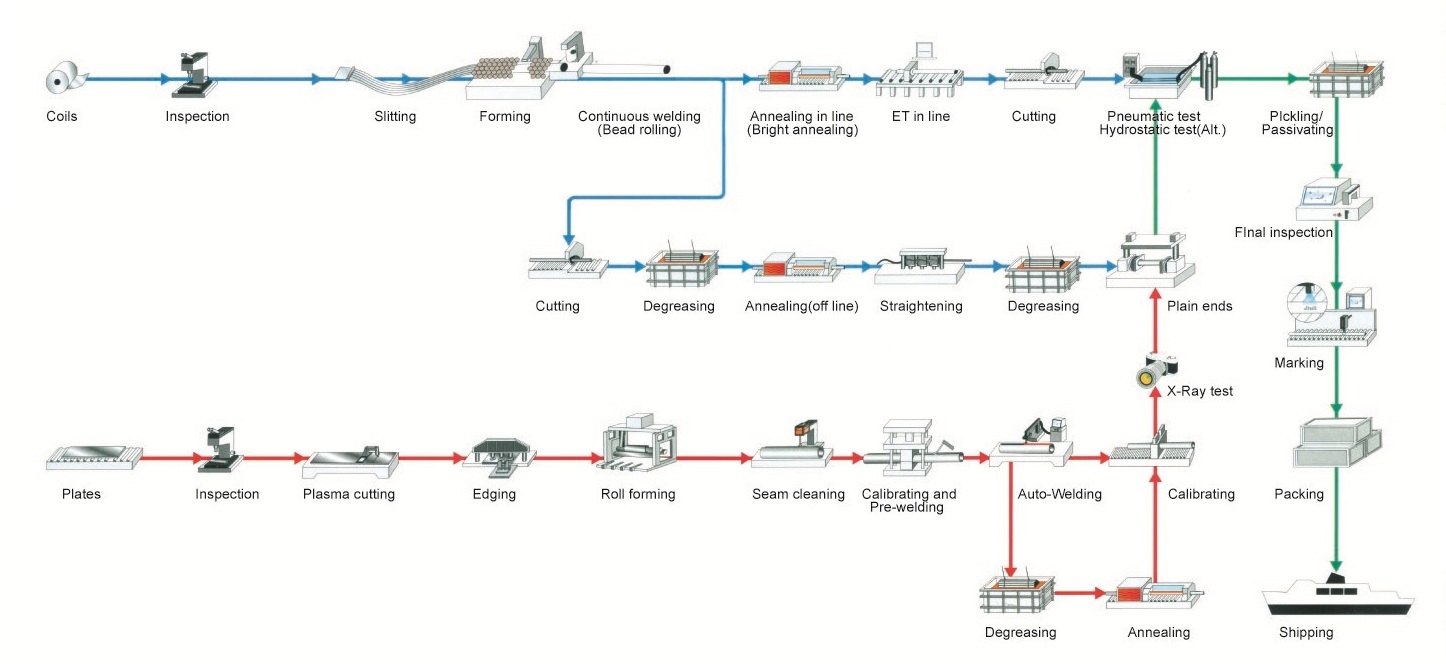

Production process

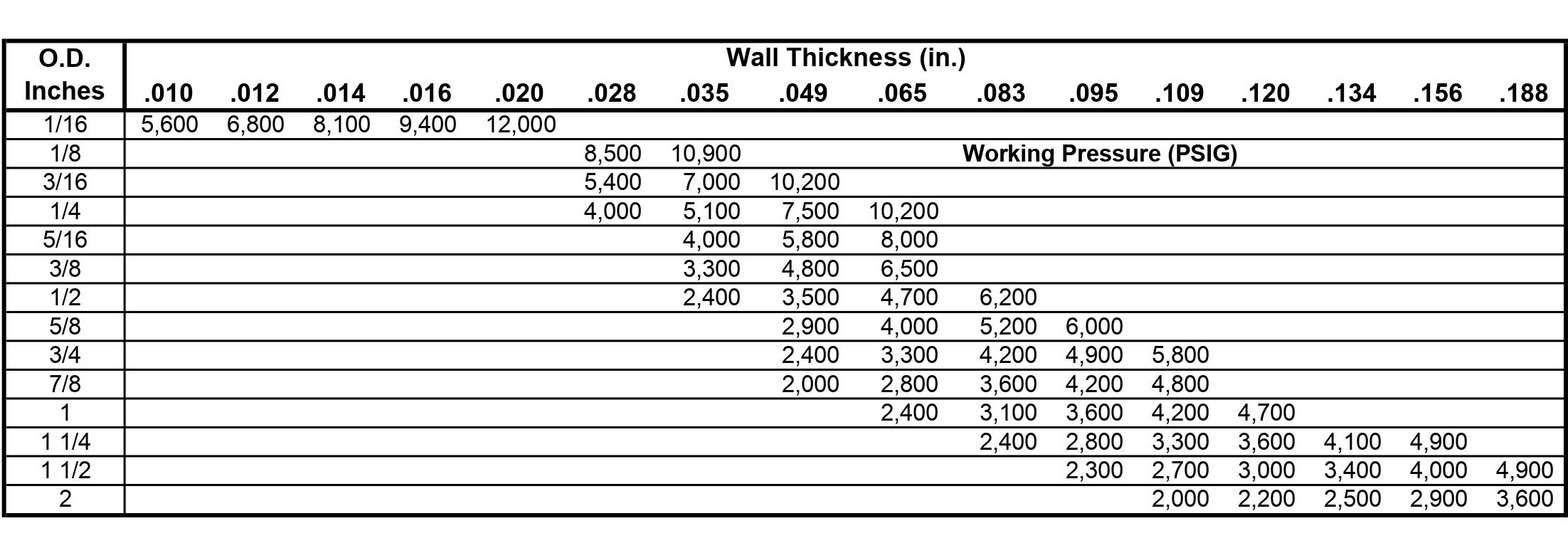

Working pressures for seamless tubing

Xinhang Special Material Co., Ltd. Hangzhou Branch is famous China High Strength 316L Stainless Steel Heat Exchange Tube For Boiler suppliers and OEM/ODM High Strength 316L Stainless Steel Heat Exchange Tube For Boiler manufacturers, founded in 2007 and moved to Longyou Economic Development Zone, Zhejiang Province, in 2022. It covers an area of 130,000 square meters, more than 30 production lines, 300 workers, 20 R&D people, 30 inspection people and an annual output of 50,000 tons.

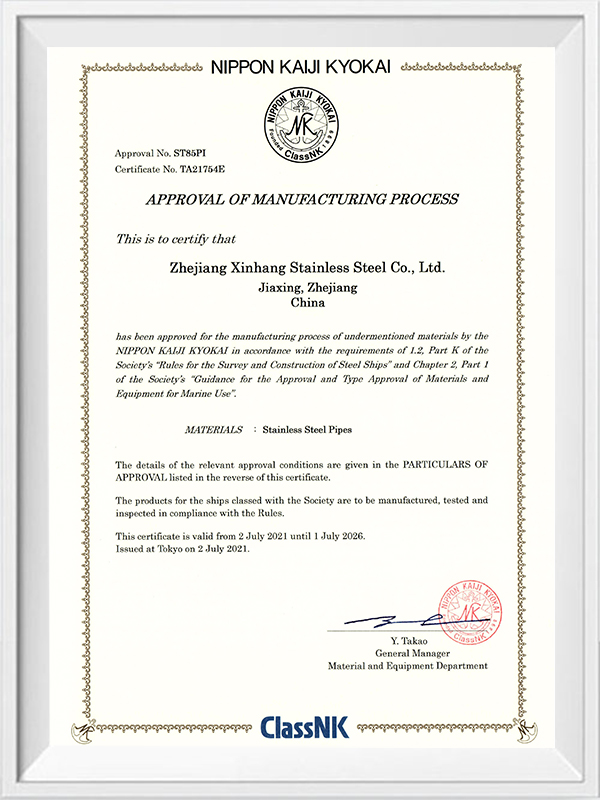

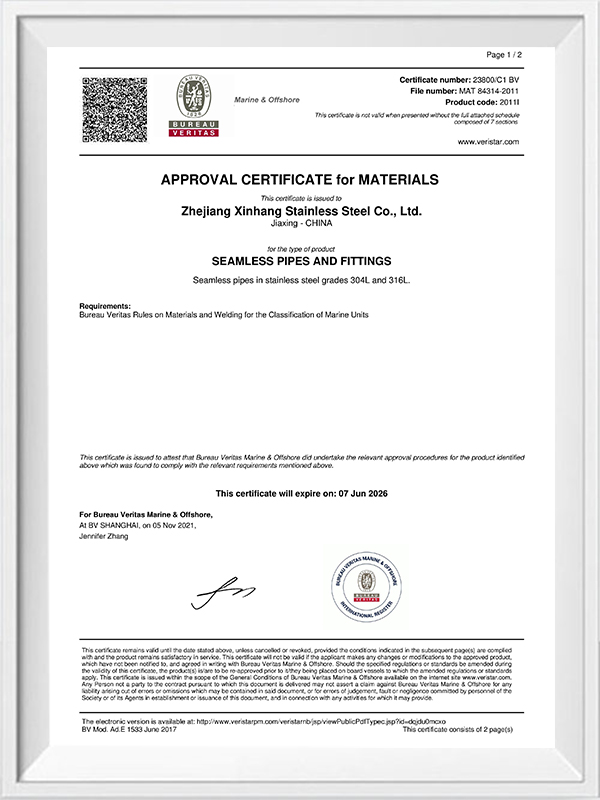

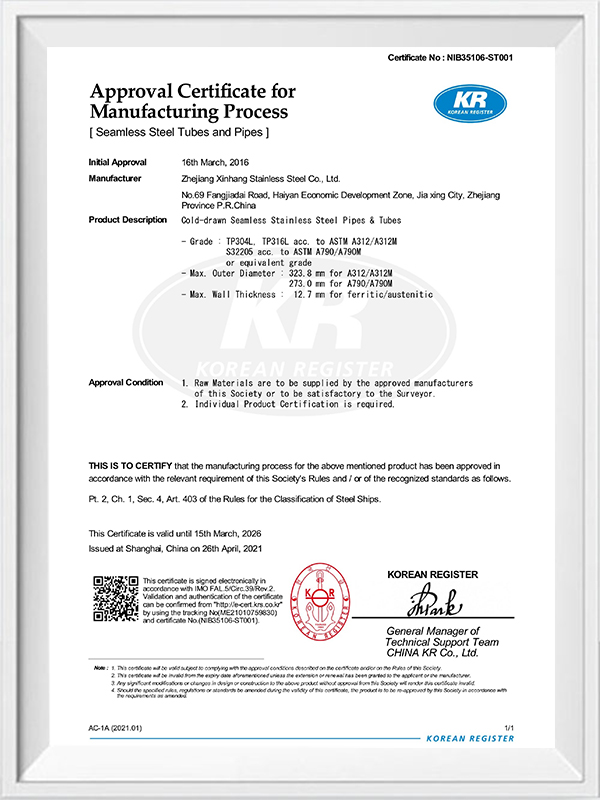

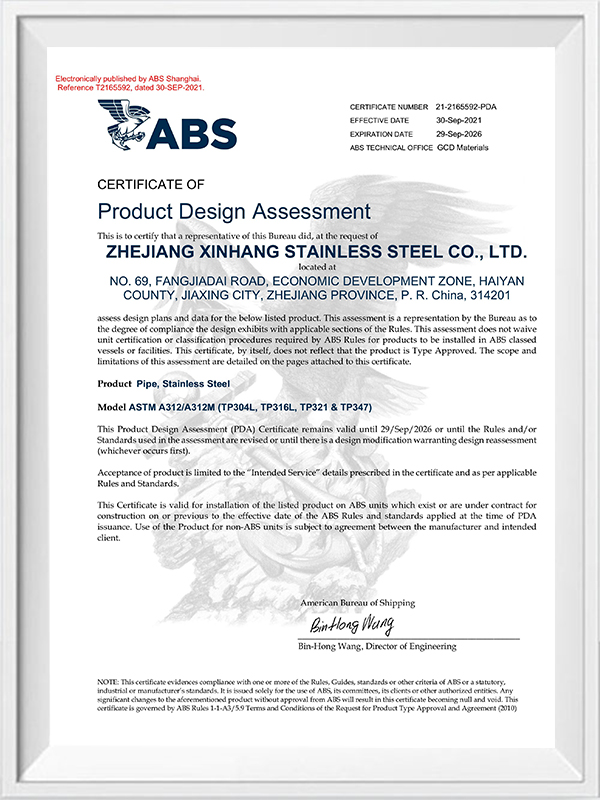

It has passed ISO9001:2008 quality management system, PED 97/23/EC EU Pressure Equipment Directive certification, China Special Equipment Manufacturing License (Pressure Tube) TS certification, ASME certification, provincial enterprise standardization management system, ISO14000:2004 environment management system, cleaner production (green enterprise), and a series of certifications, as well as China Classification Society (CCS), American Bureau of Shipping (ABS), British Register of Shipping (LR), Deutsche Veritas (GL), Bureau Veritas Society (BV), Det Norske Veritas (DNV), and Korean Register of Shipping (KR) factory certification.

The main products include stainless steel pipes, pipe fittings, flanges, valves, etc., which are widely used in petroleum, chemical industry, nuclear industry, smelting, shipbuilding, pharmaceuticals, food, water conservancy, electric power, new energy, mechanical equipment, and other fields. The company adheres to the corporate tenet of "quality for survival, reputation for development" and wholeheartedly serves every customer to create a win-win situation.

“Corten” is a common market name for weathering steel—low-alloy structural steels engineered to form a protective oxide “patina” in the right exposure conditions. This article focuses on corten steel ...

View MoreIntroduction to Alloy Steel Alloy steel is a type of steel that is made by combining carbon steel with various alloying elements such as chromium, nickel, molybdenum, and vanadium. These alloying elem...

View MoreMass Density of Mild Steel: Basics and Practical Importance The mass density of mild steel is a fundamental property that directly affects how engineers and designers size components, estimate weight,...

View MoreWe'll never share your email address and you

can opt out at any time, we promise.