Long weld neck flanges are an extension of welding neck flanges with necks. It is typically used in applications that involve high pressure as well as high or low temperatures conditions. Such as in oil and gas pipelines, chemical processing plants, and power generation facilities.

The neck of the flange is a one-piece forged flange with a long, tapered neck and a flat face or raised face. The long neck allows for a smooth transition from the pipe to the flange, which helps to distribute stresses more evenly and reduces the risk of fatigue failure. In addition, the long neck provides sufficient space for welding, which can further enhance the integrity and performance of the pipeline.

The neck of the long welding neck flange is considerably longer than other flanges, so it often used as a nozzle for a barrel or column. It can be directly attached to the vessel. This allows them to be considered as a nozzle that is reinforced. The use of this flange type means that a pipe to flange weld seam can be avoided. It also provides the benefits of self -enhancement.

Introduction

|

Standard |

Carbon Steel: ASTM A105, ASTM A350 LF1/ LF2, S235JR, P245GH, P250GH, P280GH, A694 F42/ 46 /52 /56 / 60 / 65 / 70, etc Stainless Steel: ASTM A182 F304/304L/304H, F316/316L,F317/317L,F321,F310,F347,Etc. Alloy Steel: ASTM A 182 F1/ F5/ F9/ F11/ F22/ F91/ Etc. Duplex and super duplex steel: ASTM A815 UNS S31803/S32205/S32750/S32760 |

|

Material |

A182 F304/304L, F316/316L, 317, 321, 310s, 316ti, 316H.317H.317L. 904L, 321H,347H, 310H, UNS31803, UNS32750, UNS32760 , nickel alloy inconel 600, inconel 625, inconel 601, inconel 690, inconel 625,inconel 718,incoloy 800, incoloy 825, incoloy 800h, C-276,monel 400, alloy 20 etc. |

|

Surface |

Rust Prevention, Black Paint Coating or Phosphating Treatment with Black Color, Varnish Paint Coating, Varnish Oil Coating, Electro Galvanizing Coating |

|

Type |

Forged, Heat-treated and machined |

|

size |

1/2"-48" |

|

Delivery time |

Within 5-30 days after receiving the prepaid |

|

Packing |

Inner Plastic Bag, Outer Carton, and Plywood Case or Pallet or according to the client's requirement |

|

Application |

Water works, Shipbuilding industry, Petrochemical & Gas industry, Power |

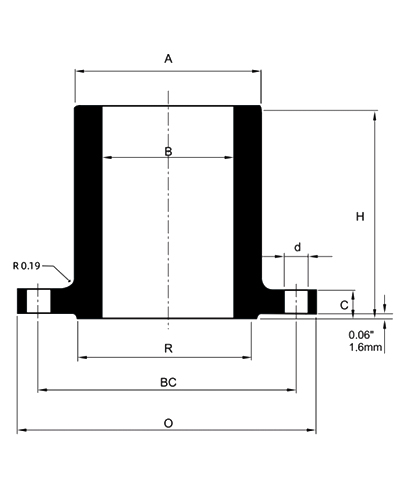

FLANGE TOLERANCES

GENERAL NOTE: Dimensions are in inches.

|

|

|

|

Outside Diameter (dimension O) |

OD <12 ±0.060 OD >12, <24 ±0.120 OD >24 ±0.190 |

|

|

|

|

Thickness of Flange Min(dimension C) |

All Sizes NPS 18 and smaller +0.120, -zero NPS 20 and larger +0.190, -zero |

|

Hub Diameter Bevel (dimension A) |

All Sizes +0.120, -zero |

|

Length Through Hub (dimension H) |

NPS 4 and smaller ±0.060 NPS 5 to 10, inclusive +0.060, -0.120 NPS 12 and larger +0.120, -0.180 |

|

Diameter of Bore (dimension B) |

NPS 10 and smaller ±0.030 NPS 12 to 18, inclusive ±0.060 NPS 20 and larger +0.120, -0.060 |

|

Facings |

*Facing Height ±0.010 Diameter of raised face (dimension R) Class 150, 300 (0.06 in. raised face) ±0.030 Class 400 + (0.25 in. raised face) ±0.020 Ring Type Joint +0.020, -zero Inside and outside diameters of large and small tongue, groove, male, and female R, S, T, U, W, X, Y & Z ±0.020 K & L +0.020, -zero Ring Joint Facing Depth (dimension E) +0.016, -zero Width (dimension F) ±0.008 Pitch diameter (dimension P) ±0.005 Radius at the bottom (dimension R) R < 0.060 +0.030, -zero R > 0.060 ±0.030 23-degree angle ±½ deg. |

|

Drilling and Facing |

Diameter of the bolt circle ±0.060 Center-to-center of adjacent bolt holes ±0.030 Eccentricity between bolt circle and diameter and machined facing diameters NPS 2 ½ and smaller ±0.030 NPS 3 and larger ±0.060 *Diameter of bolt holes ±0.020 |

CLASS150

|

Nominal Pipe Size (IN) |

Outside Diameter (MM) |

Thickness of Flange Min. (MM) |

O.D. Of Raised Face (MM) |

Hub Diameter at Bevel (MM) |

Diameter of Bore (MM) |

Length Through Hub (MM) |

Drilling |

||

|

Diameter of Bolt Circle (MM) |

Number of Holes |

Diameter of Holes (MM) |

|||||||

|

- |

O |

C |

R |

A |

B |

H |

BC |

- |

d |

|

½ |

89.0 |

11.1 |

34.9 |

30.2 |

12.7 |

228.6 |

60.5 |

4 |

15.8 |

|

¾ |

95.8 |

12.7 |

42.9 |

38.1 |

19.1 |

228.6 |

69.9 |

4 |

15.8 |

|

1 |

10.8.0 |

14.3 |

50.8 |

50.8 |

25.4 |

228.6 |

79.4 |

4 |

15.8 |

|

1 ¼ |

117.5 |

15.9 |

63.5 |

60.3 |

31.8 |

228.6 |

88.9 |

4 |

15.8 |

|

1 ½ |

127.0 |

17.5 |

73.0 |

66.7 |

38.1 |

228.6 |

98.4 |

4 |

15.8 |

|

2 |

152.5 |

19.1 |

92.1 |

82.5 |

50.8 |

228.6 |

120.7 |

4 |

19.0 |

|

2 ½ |

178.0 |

22.2 |

104.8 |

95.2 |

63.5 |

228.6 |

139.7 |

4 |

19.0 |

|

3 |

190.5 |

23.8 |

127.0 |

107.9 |

76.2 |

228.6 |

152.4 |

4 |

19.0 |

|

3 ½ |

216.0 |

23.8 |

139.9 |

124.0 |

88.9 |

228.6 |

177.8 |

8 |

19.0 |

|

4 |

228.5 |

23.8 |

157.2 |

139.7 |

101.6 |

228.6 |

190.5 |

8 |

19.0 |

|

5 |

254.0 |

23.8 |

185.7 |

165.1 |

127.0 |

228.6 |

215.9 |

8 |

22.5 |

|

6 |

279.5 |

25.4 |

215.9 |

196.8 |

152.4 |

228.6 |

241.3 |

8 |

22.5 |

|

8 |

343.0 |

28.6 |

269.9 |

247.6 |

203.2 |

228.6 |

298.4 |

8 |

22.5 |

|

10 |

406.5 |

30.2 |

323.9 |

304.8 |

254.0 |

228.6 |

361.9 |

12 |

25.5 |

|

12 |

482.5 |

31.8 |

381.0 |

365.1 |

304.8 |

228.6 |

431.8 |

12 |

25.5 |

|

14 |

533.5 |

34.9 |

412.8 |

406.4 |

355.6 |

228.6 |

476.2 |

12 |

28.5 |

|

16 |

597.0 |

36.5 |

469.9 |

457.2 |

406.4 |

228.6 |

539.7 |

16 |

28.5 |

|

18 |

635.0 |

39.7 |

533.4 |

508.0 |

457.2 |

228.6 |

577.8 |

16 |

31.8 |

|

20 |

698.5 |

42.9 |

584.2 |

558.8 |

508.0 |

228.6 |

635.0 |

20 |

31.8 |

|

24 |

813.0 |

47.0 |

692.2 |

666.7 |

609.6 |

228.6 |

749.3 |

20 |

35.1 |

CLASS300

|

Nominal Pipe Size (IN) |

Outside Diameter (MM) |

Thickness of Flange Min. (MM) |

O.D. Of Raised Face (MM) |

Hub Diameter at Bevel (MM) |

Diameter of Bore (MM) |

Length Through Hub (MM) |

Drilling |

||

|

Diameter of Bolt Circle (MM) |

Number of Holes (PC) |

Diameter of Holes (MM) |

|||||||

|

- |

O |

C |

R |

A |

B |

H |

BC |

- |

d |

|

½ |

95.5 |

14.3 |

34.9 |

38.1 |

12.7 |

228.6 |

66.7 |

4 |

15.8 |

|

¾ |

117.5 |

15.9 |

42.9 |

47.6 |

19.1 |

228.6 |

82.5 |

4 |

19.0 |

|

1 |

124.0 |

17.5 |

50.8 |

54.0 |

25.4 |

228.6 |

88.9 |

4 |

19.0 |

|

1 ¼ |

133.5 |

19.1 |

63.5 |

63.5 |

31.8 |

228.6 |

98.4 |

4 |

19.0 |

|

1 ½ |

155.5 |

20.6 |

73.0 |

69.8 |

38.1 |

228.6 |

114.3 |

4 |

22.5 |

|

2 |

165.0 |

22.2 |

92.1 |

82.5 |

50.8 |

228.6 |

127.0 |

8 |

19.0 |

|

2 ½ |

190.5 |

25.4 |

104.8 |

100.0 |

63.5 |

228.6 |

149.2 |

8 |

22.5 |

|

3 |

209.5 |

28.6 |

127.0 |

117.5 |

76.2 |

228.6 |

168.3 |

8 |

22.5 |

|

3 ½ |

228.5 |

30.2 |

139.7 |

133.4 |

88.9 |

228.6 |

184.1 |

8 |

22.5 |

|

4 |

254.0 |

31.8 |

157.2 |

146.0 |

101.6 |

228.6 |

200.0 |

8 |

22.5 |

|

5 |

279.5 |

34.9 |

185.7 |

177.8 |

127.0 |

228.6 |

234.9 |

8 |

22.5 |

|

6 |

317.5 |

36.5 |

215.9 |

206.4 |

152.4 |

228.6 |

269.9 |

12 |

22.5 |

|

8 |

381.0 |

41.3 |

269.9 |

260.3 |

203.2 |

228.6 |

330.2 |

12 |

25.5 |

|

10 |

444.5 |

47.6 |

323.9 |

320.7 |

254.0 |

228.6 |

387.3 |

16 |

28.5 |

|

12 |

520.5 |

50.8 |

381.0 |

374.6 |

304.8 |

228.6 |

450.8 |

16 |

31.8 |

|

14 |

584.0 |

54.0 |

412.8 |

425.4 |

355.6 |

228.6 |

514.3 |

20 |

31.8 |

|

16 |

64.7 |

57.2 |

469.9 |

482.6 |

406.4 |

228.6 |

571.5 |

20 |

35.1 |

|

18 |

711.0 |

60.3 |

533.4 |

533.4 |

457.2 |

228.6 |

628.6 |

24 |

35.1 |

|

20 |

774.5 |

63.5 |

584.2 |

587.3 |

508.0 |

228.6 |

685.8 |

24 |

35.1 |

|

24 |

914.5 |

69.9 |

692.2 |

701.6 |

609.6 |

228.6 |

812.8 |

24 |

41.2 |

CLASS400

|

Nominal Pipe Size (IN) |

Outside Diameter (MM) |

Thickness of Flange Min. (MM) |

O.D. Of Raised Face (MM) |

Hub Diameter at Bevel (MM) |

Diameter of Bore (MM) |

Length Through Hub (MM) |

Drilling |

||

|

Diameter of Bolt Circle (MM) |

Number of Holes (PC) |

Diameter of Holes (MM) |

|||||||

|

- |

O |

C |

R |

A |

B |

H |

BC |

- |

d |

|

1 |

124.0 |

17.5 |

50.8 |

54.0 |

25.4 |

228.6 |

88.9 |

4 |

19.0 |

|

1 ¼ |

133.5 |

20.6 |

63.5 |

63.5 |

31.8 |

228.6 |

98.4 |

4 |

19.0 |

|

1 ½ |

155.5 |

22.2 |

73.0 |

69.8 |

38.1 |

228.6 |

114.3 |

4 |

22.5 |

|

2 |

165.0 |

25.4 |

92.1 |

82.5 |

50.8 |

228.6 |

127.0 |

8 |

19.0 |

|

2 ½ |

190.5 |

28.6 |

104.8 |

100.0 |

63.5 |

228.6 |

149.2 |

8 |

22.5 |

|

3 |

209.5 |

31.8 |

127.0 |

117.5 |

76.2 |

228.6 |

168.1 |

8 |

22.5 |

|

3 ½ |

228.5 |

34.9 |

139.7 |

133.4 |

88.9 |

228.6 |

184.2 |

8 |

25.5 |

|

4 |

254.0 |

34.9 |

157.2 |

146.0 |

101.6 |

228.6 |

200.0 |

8 |

25.5 |

|

5 |

279.5 |

38.1 |

185.7 |

177.8 |

127.0 |

228.6 |

234.9 |

8 |

25..5 |

|

6 |

317.5 |

41.3 |

215.9 |

206.4 |

152.4 |

228.6 |

269.9 |

12 |

25.5 |

|

8 |

381.0 |

47.6 |

269.9 |

260.3 |

203.2 |

228.6 |

330.2 |

12 |

28.5 |

|

10 |

444.5 |

54.0 |

323.9 |

320.7 |

254.0 |

228.6 |

387.3 |

16 |

31.8 |

|

12 |

520.5 |

57.2 |

381.0 |

374.6 |

304.8 |

228.6 |

450.8 |

16 |

35.1 |

|

14 |

584.0 |

60.3 |

412.8 |

425.4 |

355.6 |

228.6 |

514.3 |

20 |

35.1 |

|

16 |

647.5 |

63.5 |

469.9 |

482.6 |

406.4 |

228.6 |

571.5 |

20 |

38.1 |

|

18 |

711.0 |

66.7 |

533.4 |

533.4 |

457.2 |

228.6 |

628.6 |

24 |

38.1 |

|

20 |

774.5 |

69.9 |

584.2 |

587.3 |

508.0 |

228.6 |

685.8 |

24 |

41.2 |

|

24 |

914.5 |

76.2 |

692.2 |

701.6 |

609.6 |

228.6 |

812.8 |

24 |

47.8 |

CLASS600

|

Nominal Pipe Size (IN) |

Outside Diameter (MM) |

Thickness of Flange Min. (MM) |

O.D. Of Raised Face (MM) |

Hub Diameter at Bevel (MM) |

Diameter of Bore (MM) |

Length Through Hub (MM) |

Drilling |

||

|

Diameter of Bolt Circle (MM) |

Number of Holes (PC) |

Diameter of Holes (MM) |

|||||||

|

- |

O |

C |

R |

A |

B |

H |

BC |

- |

d |

|

1 |

124.0 |

17.5 |

50.8 |

54.0 |

25.4 |

228.6 |

88.9 |

4 |

19.0 |

|

1 ¼ |

133.5 |

20.6 |

63.5 |

63.5 |

31.8 |

228.6 |

98.4 |

4 |

19.0 |

|

1 ½ |

155.5 |

22.2 |

73.0 |

69.8 |

38.1 |

228.6 |

114.3 |

4 |

22.5 |

|

2 |

165.0 |

25.4 |

92.1 |

82.5 |

50.8 |

228.6 |

127.0 |

8 |

19.0 |

|

2 ½ |

190.5 |

28.6 |

104.8 |

100.0 |

63.5 |

228.6 |

149.2 |

8 |

22.5 |

|

3 |

209.5 |

31.8 |

127.0 |

117.5 |

76.2 |

228.6 |

168.1 |

8 |

22.5 |

|

3 ½ |

228.5 |

34.9 |

139.7 |

133.4 |

88.9 |

228.6 |

184.2 |

8 |

25.5 |

|

4 |

273.0 |

38.1 |

157.2 |

152.4 |

101.6 |

228.6 |

215.9 |

8 |

25.5 |

|

5 |

330.0 |

44.5 |

185.7 |

190.5 |

127.0 |

228.6 |

266.7 |

8 |

28.5 |

|

6 |

355.5 |

47.6 |

215.9 |

222.2 |

152.4 |

228.6 |

292.1 |

12 |

28.5 |

|

8 |

419 |

55.6 |

269.9 |

273.0 |

203.2 |

228.6 |

349.3 |

12 |

31.8 |

|

10 |

508.0 |

63.5 |

323.9 |

342.9 |

254.0 |

228.6 |

431.8 |

16 |

35.1 |

|

12 |

559.0 |

66.7 |

381.0 |

400.0 |

304.8 |

228.6 |

489.0 |

20 |

35.1 |

|

14 |

603.5 |

69.9 |

412.8 |

431.8 |

355.6 |

228.6 |

527.1 |

20 |

38.1 |

|

16 |

686.0 |

76.2 |

469.9 |

495.3 |

406.4 |

228.6 |

603.3 |

20 |

412 |

|

18 |

743.0 |

82.6 |

533.4 |

546.1 |

457.2 |

228.6 |

654.1 |

20 |

44.5 |

|

20 |

813.0 |

88.9 |

584.2 |

609.6 |

508.0 |

228.6 |

723.9 |

24 |

44.5 |

|

24 |

940.0 |

101.6 |

692.2 |

717.5 |

609.6 |

228.6 |

838.2 |

24 |

50.8 |

CLASS900

|

Nominal Pipe Size (IN) |

Outside Diameter (MM) |

Thickness of Flange Min. (MM) |

O.D. Of Raised Face (MM) |

Hub Diameter at Bevel (MM) |

Diameter of Bore (MM) |

Length Through Hub (MM) |

Drilling |

||

|

Diameter of Bolt Circle (MM) |

Number of Holes (PC) |

Diameter of Holes (MM) |

|||||||

|

- |

O |

C |

R |

A |

B |

H |

BC |

- |

d |

|

1 |

149.5 |

28.6 |

50.8 |

52.4 |

25.4 |

228.6 |

101.6 |

4 |

25.5 |

|

1 ¼ |

159.0 |

28.6 |

63.5 |

63.5 |

31.8 |

228.6 |

111.1 |

4 |

25.5 |

|

1 ½ |

178.0 |

31.8 |

73.0 |

69.9 |

38.1 |

228.6 |

123.8 |

4 |

28.5 |

|

2 |

216.0 |

38.1 |

92.1 |

104.8 |

50.8 |

228.6 |

165.1 |

8 |

25.5 |

|

2 ½ |

244.5 |

41.3 |

104.8 |

123.8 |

63.5 |

228.6 |

190.5 |

8 |

28.5 |

|

3 |

241.5 |

38.1 |

127.0 |

127.0 |

76.2 |

228.6 |

190.5 |

8 |

25.5 |

|

4 |

292.0 |

44.5 |

157.2 |

158.7 |

101.6 |

228.6 |

235.0 |

8 |

31.8 |

|

5 |

349.5 |

50.8 |

185.7 |

190.5 |

127.0 |

228.6 |

279.4 |

8 |

35.1 |

|

6 |

381.0 |

55.6 |

215.9 |

235.0 |

152.4 |

228.6 |

317.5 |

12 |

31.8 |

|

8 |

470.0 |

63.5 |

269.9 |

298.5 |

203.2 |

228.6 |

393.7 |

12 |

38.1 |

|

10 |

546.0 |

69.9 |

323.9 |

368.3 |

254.0 |

228.6 |

469.9 |

16 |

38.1 |

|

12 |

609.5 |

79.4 |

381.0 |

419.1 |

304.8 |

228.6 |

533.5 |

20 |

38.1 |

|

14 |

641.5 |

85.7 |

412.8 |

450.9 |

355.6 |

228.6 |

558.8 |

20 |

41.0 |

|

16 |

705.0 |

88.9 |

469.9 |

508.0 |

406.4 |

228.6 |

616.0 |

20 |

44.5 |

|

18 |

787.5 |

101.6 |

533.4 |

565.2 |

457.2 |

228.6 |

685.8 |

20 |

50.8 |

|

20 |

857.5 |

108.0 |

584.2 |

622.3 |

508.0 |

228.6 |

749.3 |

20 |

54.0 |

|

24 |

1014.5 |

139.7 |

692.2 |

749.3 |

609.6 |

228.6 |

901.7 |

20 |

66.5 |

CLASS1500

|

Nominal Pipe Size (IN) |

Outside Diameter (MM) |

Thickness of Flange Min. (MM) |

O.D. Of Raised Face (MM) |

Hub Diameter at Bevel (MM) |

Diameter of Bore (MM) |

Length Through Hub (MM) |

Drilling |

||

|

Diameter of Bolt Circle (MM) |

Number of Holes (PC) |

Diameter of Holes (MM) |

|||||||

|

- |

O |

C |

R |

A |

B |

H |

BC |

- |

d |

|

1 |

149.5 |

28.6 |

50.8 |

52.4 |

25.4 |

228.6 |

101.6 |

4 |

25.5 |

|

1 ¼ |

159.0 |

28.6 |

63.5 |

63.5 |

31.8 |

228.6 |

111.1 |

4 |

25.5 |

|

1 ½ |

178.0 |

31.8 |

73.0 |

69.9 |

38.1 |

228.6 |

123.8 |

4 |

28.5 |

|

2 |

216.0 |

38.1 |

92.1 |

104.8 |

50.8 |

228.6 |

165.1 |

8 |

25.5 |

|

2 ½ |

244.5 |

41.3 |

104.8 |

123.8 |

63.5 |

228.6 |

190.5 |

8 |

28.5 |

|

3 |

267.0 |

47.6 |

127.0 |

133.4 |

762 |

228.6 |

203.2 |

8 |

31.8 |

|

4 |

311.0 |

54.0 |

157.2 |

161.9 |

101.6 |

228.6 |

241.3 |

8 |

35.1 |

|

5 |

374.5 |

73.0 |

185.7 |

196.9 |

127.0 |

228.6 |

292.1 |

8 |

41.0 |

|

6 |

393.5 |

82.6 |

215.9 |

228.6 |

152.4 |

228.6 |

317.5 |

12 |

38.1 |

|

8 |

483.0 |

92.1 |

269.9 |

292.1 |

203.2 |

228.6 |

393.7 |

12 |

44.5 |

|

10 |

584.0 |

108.0 |

323.9 |

368.3 |

254.0 |

406.4 |

482.6 |

12 |

50.8 |

|

12 |

673.0 |

123.8 |

381.0 |

450.9 |

304.8 |

406.4 |

571.5 |

16 |

54.0 |

|

14 |

749.5 |

133.4 |

412.8 |

495.3 |

355.6 |

- |

635.0 |

16 |

60.5 |

|

16 |

825.5 |

146.1 |

469.9 |

552.6 |

406.4 |

- |

704.9 |

16 |

66.5 |

|

18 |

914.5 |

161.9 |

533.4 |

596.9 |

457.2 |

- |

774.7 |

16 |

73.0 |

|

20 |

984.0 |

177.8 |

584.2 |

641.4 |

508.0 |

- |

831.9 |

16 |

79.5 |

|

24 |

1168.5 |

203.2 |

692.2 |

762.0 |

609.6 |

- |

9910.6 |

16 |

920 |

CLASS2500

|

Nominal Pipe Size (IN) |

Outside Diameter (MM) |

Thickness of Flange Min. (MM) |

O.D. Of Raised Face (MM) |

Hub Diameter at Bevel (MM) |

Diameter of Bore (MM) |

Length Through Hub (MM) |

Drilling |

||

|

Diameter of Bolt Circle (MM) |

Number of Holes (PC) |

Diameter of Holes (MM) |

|||||||

|

- |

O |

C |

R |

A |

B |

H |

BC |

- |

d |

|

1 |

159.0 |

34.9 |

50.8 |

57.2 |

25.4 |

228.6 |

108.0 |

4 |

25.5 |

|

1 ¼ |

184.0 |

38.1 |

63.5 |

73.0 |

31.8 |

228.6 |

130.2 |

4 |

28.5 |

|

1 ½ |

203.0 |

44.5 |

73.0 |

79.4 |

38.1 |

228.6 |

146.1 |

4 |

31.8 |

|

2 |

235.0 |

50.8 |

92.1 |

95.3 |

50.8 |

228.6 |

171.5 |

8 |

28.5 |

|

2 ½ |

267.0 |

57.2 |

104.8 |

114.3 |

63.5 |

228.6 |

196.9 |

8 |

31.8 |

|

3 |

305.0 |

66.7 |

127.0 |

133.4 |

76.2 |

228.6 |

228.6 |

8 |

35.0 |

|

4 |

355.5 |

76.2 |

157.2 |

165.1 |

101.6 |

228.6 |

273.1 |

8 |

41.0 |

|

5 |

419.0 |

92.1 |

185.7 |

203.2 |

127.0 |

228.6 |

323.9 |

8 |

48.0 |

|

6 |

483.0 |

108.0 |

215.9 |

235.0 |

152.4 |

228.6 |

368.3 |

8 |

54.0 |

|

8 |

552.5 |

127.0 |

269.9 |

304.8 |

203.2 |

228.6 |

438.2 |

12 |

54.0 |

|

10 |

673.0 |

165.1 |

323.9 |

374.7 |

254.0 |

406.4 |

539.8 |

12 |

66.5 |

|

12 |

762.0 |

184.2 |

381.0 |

441.3 |

304.8 |

406.4 |

619.1 |

12 |

73.0 |

Xinhang Special Material Co., Ltd. Hangzhou Branch is famous China Long Welded Neck Stainless Steel Material Polishing Treatment suppliers and OEM/ODM Long Welded Neck Stainless Steel Material Polishing Treatment manufacturers, founded in 2007 and moved to Longyou Economic Development Zone, Zhejiang Province, in 2022. It covers an area of 130,000 square meters, more than 30 production lines, 300 workers, 20 R&D people, 30 inspection people and an annual output of 50,000 tons.

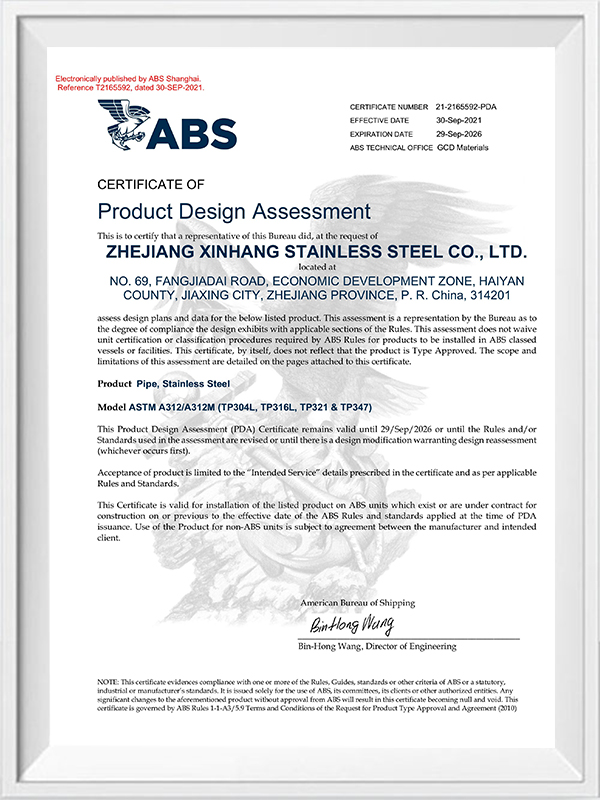

It has passed ISO9001:2008 quality management system, PED 97/23/EC EU Pressure Equipment Directive certification, China Special Equipment Manufacturing License (Pressure Tube) TS certification, ASME certification, provincial enterprise standardization management system, ISO14000:2004 environment management system, cleaner production (green enterprise), and a series of certifications, as well as China Classification Society (CCS), American Bureau of Shipping (ABS), British Register of Shipping (LR), Deutsche Veritas (GL), Bureau Veritas Society (BV), Det Norske Veritas (DNV), and Korean Register of Shipping (KR) factory certification.

The main products include stainless steel pipes, pipe fittings, flanges, valves, etc., which are widely used in petroleum, chemical industry, nuclear industry, smelting, shipbuilding, pharmaceuticals, food, water conservancy, electric power, new energy, mechanical equipment, and other fields. The company adheres to the corporate tenet of "quality for survival, reputation for development" and wholeheartedly serves every customer to create a win-win situation.

Introduction to Alloy Steel Alloy steel is a type of steel that is made by combining carbon steel with various alloying elements such as chromium, nickel, molybdenum, and vanadium. These alloying elem...

View MoreMass Density of Mild Steel: Basics and Practical Importance The mass density of mild steel is a fundamental property that directly affects how engineers and designers size components, estimate weight,...

View MoreUnderstanding Stress Proof Steel Stress proof steel is a type of alloyed steel engineered to resist deformation under long-term loads. Unlike conventional steels, it maintains dimensional stability wh...

View MoreWe'll never share your email address and you

can opt out at any time, we promise.