Socket Weld Flanges(SW Flanges) have a shoulder in which a pipe is inserted; it is a guide to set the depth at which the pipe is welded to the flange.

It is fabricated by inserting the pipe end into the flange until it bottoms out against the shoulder. Then the pipe is secured by one fillet weld located on the exterior of the flange hub.

Socket welding flange designed for high-pressure small diameters piping system(≤ 4 inches, ≤ 10cm), it is a common choice for limited space components. But not suitable for highly erosive or corrosive systems.

Socket welding flange Advantages: Corrosion resistance, cryogenic strength, abrasion and erosion resistance, surface finish, magnetic properties, ductility, high-temperature resistance, stability of in-service properties, suitability for planned manufacturing techniques

Application field: Oil and Gas, Chemical Industry, Plumbing, Heating, Water Supply Systems, Power Plant, Paper & Pulp Industry, Food Processing Industry, Structural Pipe, Fabrication Industry and General Purpose Applications etc.

Introduction

|

Standard |

EN-1092, BS10, DIN, GOST, UNI, ASME B16.5, JIS, ISO, ASME B16.38, ASME B16.47 (Series A, Series B), PN, AWWA, MSS SP44, etc |

|

Material |

SS304, SS316, SS304L, SS316L, SS321, SS310 |

|

Surface |

Yellow Transparent, Zinc Plated, Oil Black Paint, Cold and Hot Dip Galvanized, Anti-rust Paint |

|

Type |

Forged, Heat Treated Machined, etc. |

|

size |

1/2″ -24″, accept customization |

|

Delivery time |

Within 5-30 days after receiving the prepaid |

|

Packing |

Wooden Case or Other Requirement |

|

Application |

Water Pipeline Industry, Natural Gas Industry, Fabrication Industry, Oil And Gas Industry, Chemical Industry, Nuclear Power Plant |

|

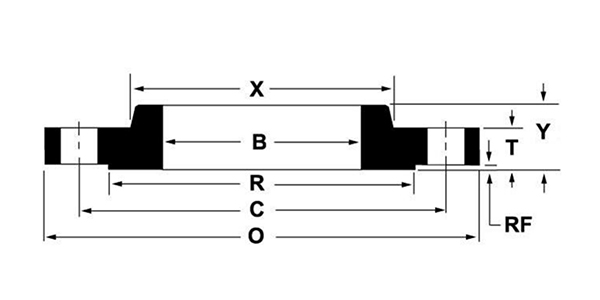

Nominal Size (in.) |

O (mm) |

T (mm) |

RF (mm) |

R (mm) |

X (mm) |

Y (mm) |

B (mm) |

D (mm) |

Number of Holes |

Diameter of Holes (mm) |

Approx. Weight Kilogram |

|

½ |

88.9 |

11.2 |

1.6 |

35.1 |

30.2 |

15.7 |

22.4 |

9.7 |

4 |

15.7 |

0.5 |

|

¾ |

98.6 |

12.7 |

1.6 |

42.9 |

38.1 |

15.7 |

27.7 |

11.2 |

4 |

15.7 |

1 |

|

1 |

108 |

14.2 |

1.6 |

50.8 |

49.3 |

17.5 |

34.5 |

12.7 |

4 |

15.7 |

1 |

|

1¼ |

117.3 |

15.7 |

1.6 |

63.5 |

58.7 |

20.6 |

43.2 |

14.2 |

4 |

15.7 |

1 |

|

1½ |

127 |

17.3 |

1.6 |

73.2 |

65 |

22.4 |

49.5 |

15.7 |

4 |

15.7 |

1 |

|

2 |

152.4 |

19.1 |

1.6 |

91.9 |

77.7 |

25.4 |

62 |

17.5 |

4 |

19.1 |

2 |

|

2½ |

177.8 |

22.4 |

1.6 |

104.6 |

90.4 |

28.4 |

74.7 |

19.1 |

4 |

19.1 |

3 |

|

3 |

190.5 |

23.9 |

1.6 |

127 |

108 |

30.2 |

90.7 |

20.6 |

4 |

19.1 |

4 |

|

3½ |

215.9 |

23.9 |

1.6 |

139.7 |

122.2 |

31.8 |

103.4 |

22.4 |

8 |

19.1 |

5 |

|

4 |

228.6 |

23.9 |

1.6 |

157.2 |

134.9 |

33.3 |

116.1 |

23.9 |

8 |

19.1 |

6 |

|

5 |

254 |

23.9 |

1.6 |

185.7 |

163.6 |

36.6 |

143.8 |

23.9 |

8 |

22.4 |

7 |

|

6 |

279.4 |

25.4 |

1.6 |

215.9 |

192 |

39.6 |

170.7 |

26.9 |

8 |

22.4 |

9 |

|

8 |

342.9 |

28.4 |

1.6 |

269.7 |

246.1 |

44.5 |

221.5 |

31.8 |

8 |

22.4 |

14 |

|

10 |

406.4 |

30.2 |

1.6 |

323.9 |

304.8 |

49.3 |

276.4 |

33.3 |

12 |

25.4 |

20 |

|

12 |

482.6 |

31.8 |

1.6 |

381 |

365.3 |

55.6 |

327.2 |

39.6 |

12 |

25.4 |

29 |

|

14 |

533.4 |

35.1 |

1.6 |

412.8 |

400.01 |

57.2 |

359.2 |

41.4 |

12 |

28.4 |

41 |

|

16 |

596.9 |

36.6 |

1.6 |

469.9 |

457.2 |

63.5 |

410.5 |

44.5 |

16 |

28.4 |

44 |

|

18 |

635 |

39.6 |

1.6 |

533.4 |

505 |

68.3 |

461.8 |

49.3 |

16 |

31.8 |

59 |

|

20 |

698.5 |

42.9 |

1.6 |

584.2 |

558.8 |

73.2 |

513.1 |

54.1 |

20 |

31.8 |

75 |

|

22 |

749.3 |

46.0 |

1.6 |

641.4 |

616.0 |

79.5 |

564.4 |

60.5 |

20 |

35.1 |

90 |

|

24 |

812.8 |

47.8 |

1.6 |

692.2 |

663.4 |

82.6 |

616 |

63.5 |

20 |

35.1 |

100 |

Xinhang Special Material Co., Ltd. Hangzhou Branch is famous China Stainless Steel Socket Weld Flange Reduces The Risk Of Leakage suppliers and OEM/ODM Stainless Steel Socket Weld Flange Reduces The Risk Of Leakage manufacturers, founded in 2007 and moved to Longyou Economic Development Zone, Zhejiang Province, in 2022. It covers an area of 130,000 square meters, more than 30 production lines, 300 workers, 20 R&D people, 30 inspection people and an annual output of 50,000 tons.

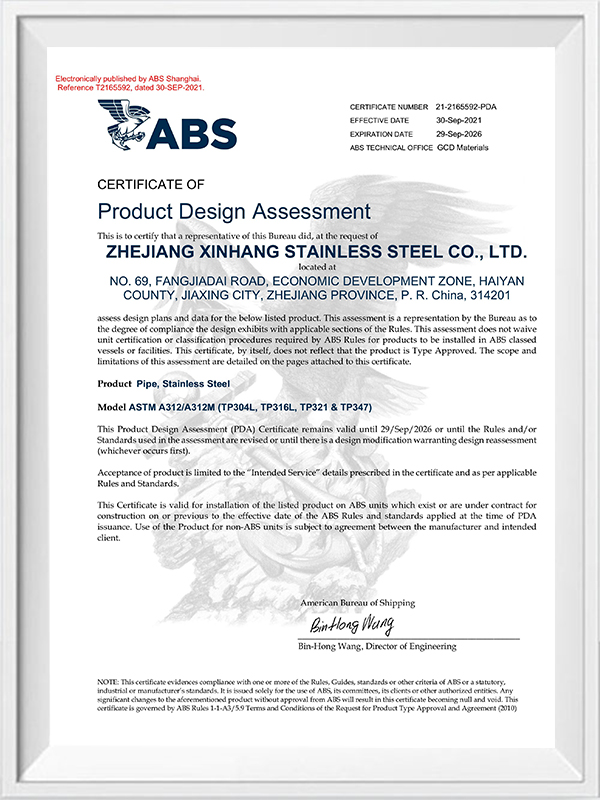

It has passed ISO9001:2008 quality management system, PED 97/23/EC EU Pressure Equipment Directive certification, China Special Equipment Manufacturing License (Pressure Tube) TS certification, ASME certification, provincial enterprise standardization management system, ISO14000:2004 environment management system, cleaner production (green enterprise), and a series of certifications, as well as China Classification Society (CCS), American Bureau of Shipping (ABS), British Register of Shipping (LR), Deutsche Veritas (GL), Bureau Veritas Society (BV), Det Norske Veritas (DNV), and Korean Register of Shipping (KR) factory certification.

The main products include stainless steel pipes, pipe fittings, flanges, valves, etc., which are widely used in petroleum, chemical industry, nuclear industry, smelting, shipbuilding, pharmaceuticals, food, water conservancy, electric power, new energy, mechanical equipment, and other fields. The company adheres to the corporate tenet of "quality for survival, reputation for development" and wholeheartedly serves every customer to create a win-win situation.

Introduction to Alloy Steel Alloy steel is a type of steel that is made by combining carbon steel with various alloying elements such as chromium, nickel, molybdenum, and vanadium. These alloying elem...

View MoreMass Density of Mild Steel: Basics and Practical Importance The mass density of mild steel is a fundamental property that directly affects how engineers and designers size components, estimate weight,...

View MoreUnderstanding Stress Proof Steel Stress proof steel is a type of alloyed steel engineered to resist deformation under long-term loads. Unlike conventional steels, it maintains dimensional stability wh...

View MoreWe'll never share your email address and you

can opt out at any time, we promise.