Instrumentation tubing refers to the tubing or tubes used to connect instruments to the main piping, to other instruments and apparatus, or to measuring equipment.

A stainless steel instrument tube is a measurement and control device based on the measurement principle and is widely used in industrial and civil fields. Its working principle is to measure and control flow through the pressure difference generated when the fluid passes through the pipeline. Set up a measuring unit in the pipeline, measure the pressure difference of the fluid in the unit, and then use the standard flow calculation formula to get the flow rate.

Since stainless steel instrument tubes should have reliable corrosion resistance and heat resistance, austenitic stainless steels are universally selected as the pressure tubing material.

1. Commonly Used Materials:

AISI & EN/DIN/ISO

ASTM / AISI: 316 /316L, 304/304L, 321/321H, 316Ti, 347 / 347H;

EN/DIN: 1.4301/1.4307, 1.4401/1.4404, 1.4541/1.4878, 1.4571.

Duplex stainless steel

ASTM / AISI: S31803, S32750,S32760, 2205, 904 / 904L.

EN/DIN: 1.4462, 1.4410, 1.4539.

The popular stainless steel grade for instrument tubing is 304 / 304L and 316 / 316L.

2. Surface Finish:

Vacuum bright annealing or protective bright annealing. Surface finish: mechanical polished 320-grit or 400-grit.

3. Dimensional Tolerances:

O.D: ± 0.0.5 mm; W.T: ± 10%; or upon request of the purchaser.

Classification and application scenarios of instrument pipelines

1. Gas Pipeline

Gas pipelines are pipelines used to transmit gas media and are generally used in gas flow meters, pressure transmitters and other instrument equipment. Gas pipelines are characterized by small diameters and fast flow rates, which require accurate measurement of flow and pressure of the gas in the pipelines. Gas pipelines are widely used in industrial fields such as petrochemical, chemical, and oxygen production.

2. Liquid pipeline

Liquid pipes are pipes used to transmit liquid media and are also one of the commonly used types of instrument pipes. Liquid pipelines are characterized by large diameters and slow flow rates. Stable flow and pressure measurements of the liquid in the pipeline are required to ensure stable and reliable system operation. Liquid pipelines are widely used in fields such as hydropower generation and sewage treatment.

3. Steam pipeline

Steam pipes are used to transport steam media, and their main purpose is to transport heat in industrial fields, such as power plants, textile factories, etc. Steam pipelines are characterized by high design pressure and temperature. It is necessary to accurately measure the flow, pressure, temperature, and other parameters of the steam in the pipeline to ensure the normal operation of the system.

4. Vacuum pipeline

Vacuum pipelines are pipelines used to transmit gas media in high vacuum environments. They are mainly used in high-tech fields such as semiconductors and photovoltaics. The characteristic of vacuum pipelines is that the pressure inside the pipeline is very low, which requires strict design and manufacturing requirements, and at the same time, the flow and pressure of the gas in the pipeline must be accurately measured.

Introduction

| Item | Stainless Steel Instrument Tube/Pipe | ||||||||||

| Standard | ASTM,JIS, AISI, GB, DIN, EN | ||||||||||

| Material | 201,202,301,304,304L,304N,XM21,304LN,309S,310S,316,316Ti,316L, 316N,316LN,317,317L,321,329,etc. |

||||||||||

| Surface | 2b/No.1/No.3/No.4/Ba/8K/Hl | ||||||||||

| Shape | Round, Square, Rectangular, Oval | ||||||||||

| Type | Cold Rolled | ||||||||||

| Test | UT, ET, HT, RT,ect, and others according to the standard,or as the requests of the customers | ||||||||||

| size | Length | 0.5-30 Meter/Customized | |||||||||

| Outer diameter | OD: 3.18mm~810mm WT: 0.2mm~40mm | ||||||||||

| Delivery time | Within 5-30 days after receiving the prepaid | ||||||||||

| Package | According to Customer Requirements | ||||||||||

Production process.jpg)

Classification of surface stainless steel

| Surface | Feature | Manufacturing Method | Usage |

| NO.1 | Silvery white, dull | Hot rolled to specified thickness | It does not need to have a shiny surface |

| NO.2D | Silvery white | After cold rolling, heat treatment and pickling are carried out | Common material, deep drawing wood |

| NO.2B | Luster is stronger than No.2D | After NO.2D treatment, a final light cold rolling is carried out on a polishing roll | Common material |

| BA | as bright as a sixpence | Non standard, but usually bright annealed surface finish with high surface reflectivity. | Building materials, kitchen utensils |

| NO.4 | Grind | A polished surface obtained by grinding with a 150~180# abrasive belt | Building materials, kitchen utensils |

| NO.240 | Fine grind | Grind with a 240# strop abrasive belt | kitchen utensils |

| NO.320 | Very fine grinding | Grind with a 320# strop abrasive belt | kitchen utensils |

| NO.400 | The gloss is close to BA | Grind with 400# polishing wheel | Common material,Building materials, kitchen utensils |

| HL | Hairline grinding | It has a large number of whetstone grains when it is used for grain grinding (150~240#) | Buildings, building materials |

| NO.8 | Mirror | The mirror is ground with a polishing wheel | Reflector, decorative |

Xinhang Special Material Co., Ltd. Hangzhou Branch is famous China Cold Process Stainless Steel Seamless Instrument Pipe For Measurement And Control Flow Device suppliers and OEM/ODM Cold Process Stainless Steel Seamless Instrument Pipe For Measurement And Control Flow Device manufacturers, founded in 2007 and moved to Longyou Economic Development Zone, Zhejiang Province, in 2022. It covers an area of 130,000 square meters, more than 30 production lines, 300 workers, 20 R&D people, 30 inspection people and an annual output of 50,000 tons.

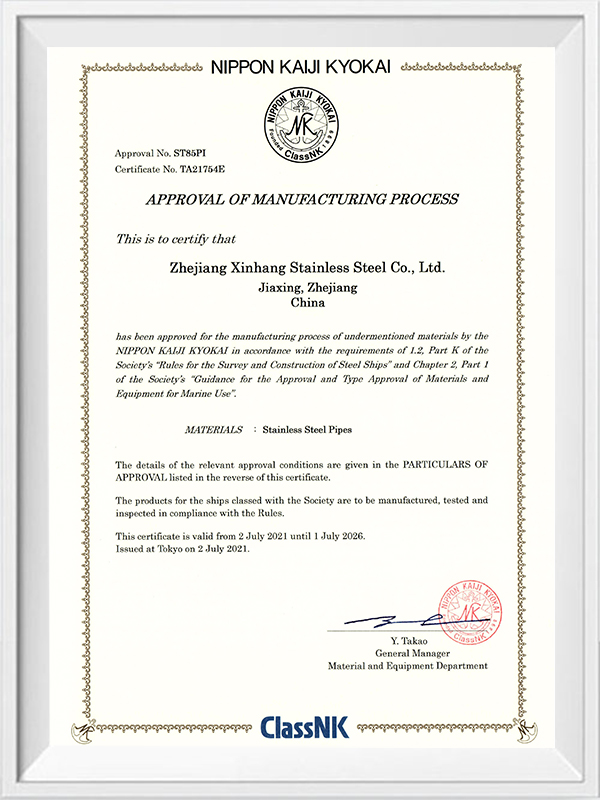

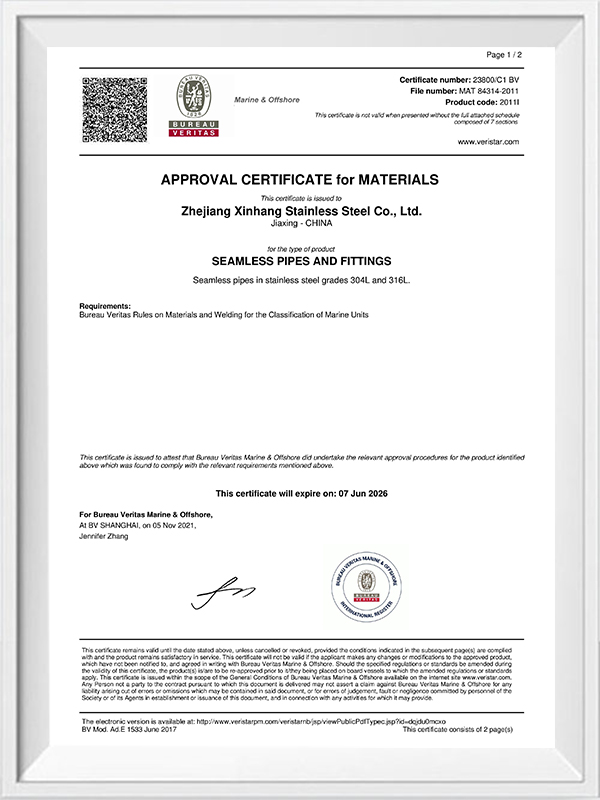

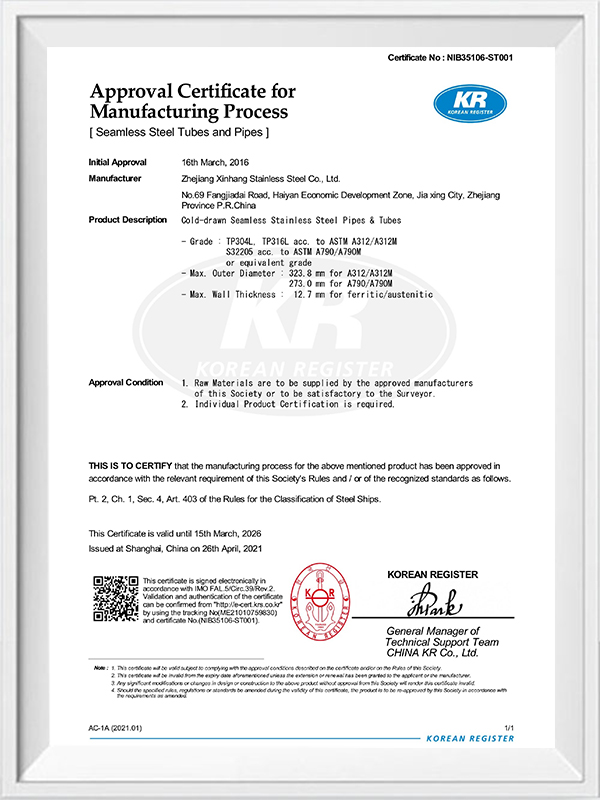

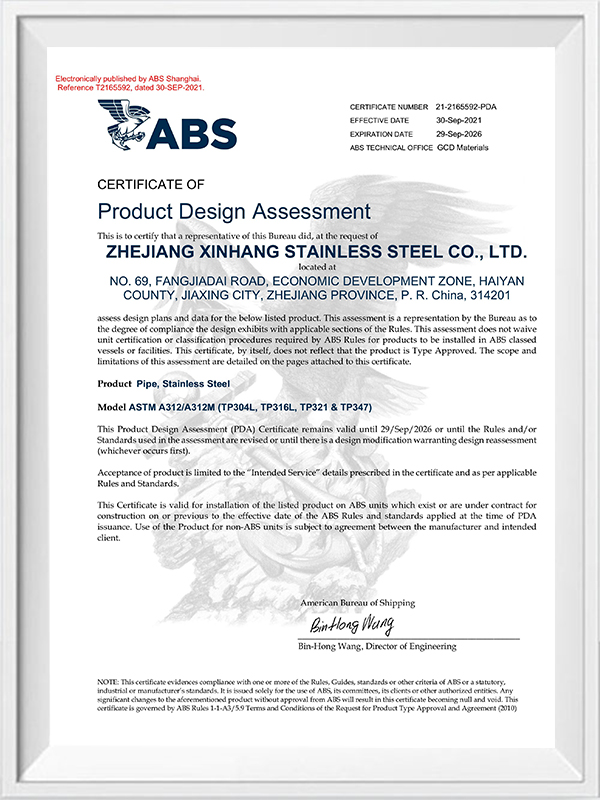

It has passed ISO9001:2008 quality management system, PED 97/23/EC EU Pressure Equipment Directive certification, China Special Equipment Manufacturing License (Pressure Tube) TS certification, ASME certification, provincial enterprise standardization management system, ISO14000:2004 environment management system, cleaner production (green enterprise), and a series of certifications, as well as China Classification Society (CCS), American Bureau of Shipping (ABS), British Register of Shipping (LR), Deutsche Veritas (GL), Bureau Veritas Society (BV), Det Norske Veritas (DNV), and Korean Register of Shipping (KR) factory certification.

The main products include stainless steel pipes, pipe fittings, flanges, valves, etc., which are widely used in petroleum, chemical industry, nuclear industry, smelting, shipbuilding, pharmaceuticals, food, water conservancy, electric power, new energy, mechanical equipment, and other fields. The company adheres to the corporate tenet of "quality for survival, reputation for development" and wholeheartedly serves every customer to create a win-win situation.

What SCH 10 stainless steel pipe specifies (and what it doesn’t) In piping specifications, “SCH” (schedule) is shorthand for wall thickness series, not material grade. For stainless applications, you...

View MoreEssential Setup for TIG Welding Stainless Steel Pipe TIG welding stainless steel pipe is unforgiving of contamination and excess heat. A repeatable setup starts with stable power delivery, consistent...

View More“Corten” is a common market name for weathering steel—low-alloy structural steels engineered to form a protective oxide “patina” in the right exposure conditions. This article focuses on corten steel ...

View MoreWe'll never share your email address and you

can opt out at any time, we promise.