The methods for polishing stainless steel tubes mainly include mechanical polishing, electrolytic polishing, chemical polishing, ultrasonic polishing, and fluid polishing. Each of these methods has its own characteristics and applicable scenarios.

1. Stainless steel mechanical polishing pipe: Polish the surface and inner wall of the stainless steel tube by using a grinding wheel or a polishing wheel. For inner wall polishing, the grinding wheel needs to be placed in the tube and polished by high-speed rotation. If higher brightness is required, the polishing paste can be added during the polishing process. 12

2. Stainless steel electrolytic polishing pipe: The stainless steel tube is used as an anode and placed in an electrolytic cell. The tiny protrusions on the surface of the steel tube are dissolved by passing a direct current to achieve a smooth surface. After polishing, the surface oxide layer may be damaged and acid passivation treatment is required to prevent rust.

3. Stainless steel chemical polishing pipe: By immersing the stainless steel tube in the configured polishing liquid, the convex and concave parts of the steel tube surface are dissolved by a chemical process to achieve a smooth effect. This method does not require complex mechanical equipment, and multiple stainless steel tubes can be polished at the same time, which improves efficiency.

4. Stainless steel ultrasonic polishing pipe: The stainless steel tube is immersed in a grinding suspension and then placed in an ultrasonic field for polishing. This method will not cause the stainless steel pipe to deform, but it is more difficult to install. Now there is also a technology that combines ultrasonic and electrochemical methods. By adding ultrasonic vibrations while electrolyzing in a chemical solution, the substances on the surface of the stainless steel pipe can be separated faster.

5. Stainless steel fluid polishing pipe: Use fast-flowing liquid and abrasive particles to flow quickly on the surface of the stainless steel pipe to achieve polishing. The flowing liquid used in this method is usually a special substance with good fluidity, and the abrasive is usually silicon carbide powder.

Among the above methods, mechanical polishing is a commonly used method. If higher precision is required, electrolytic polishing may be used. The selection of a suitable polishing method depends on the specific requirements of the stainless steel pipe, the required surface quality, and the available equipment conditions.

MP(mechanical polishing) is a widely used surface treatment technology, polishing wheel or polishing belt with the abrasive polishing agent to polish the surface of stainless steel tubes, to promote the smooth polishing effect of stainless steel tube surface.

Its brightness and effect depend on the type of processing method. The effect of polishing depends on several factors, including the type of polishing wheel and polishing belt, the choice of polishing agent, polishing pressure and polishing time, etc. In addition, although mechanical polishing is more beautiful, it will also reduce corrosion resistance to a certain extent, so when used in a corrosive environment, it needs to be passivated, and the surface of the steel pipe often has residual polishing materials. This may be due to the abrasive in the polish not being completely removed, or due to glue or other residues on the polishing strip.

To solve this problem, cleaning and decontamination treatment can be carried out after polishing to ensure the clean and smooth surface of the steel pipe. The thickness of the steel pipe may be reduced during the polishing process, so precise control is required.

Xinhang Special Material Co., Ltd. Hangzhou Branch is famous China Small Diameter Bright Seamless 316L Stainless steel MP(Mechanical Polishing) Tube suppliers and OEM/ODM Small Diameter Bright Seamless 316L Stainless steel MP(Mechanical Polishing) Tube manufacturers, founded in 2007 and moved to Longyou Economic Development Zone, Zhejiang Province, in 2022. It covers an area of 130,000 square meters, more than 30 production lines, 300 workers, 20 R&D people, 30 inspection people and an annual output of 50,000 tons.

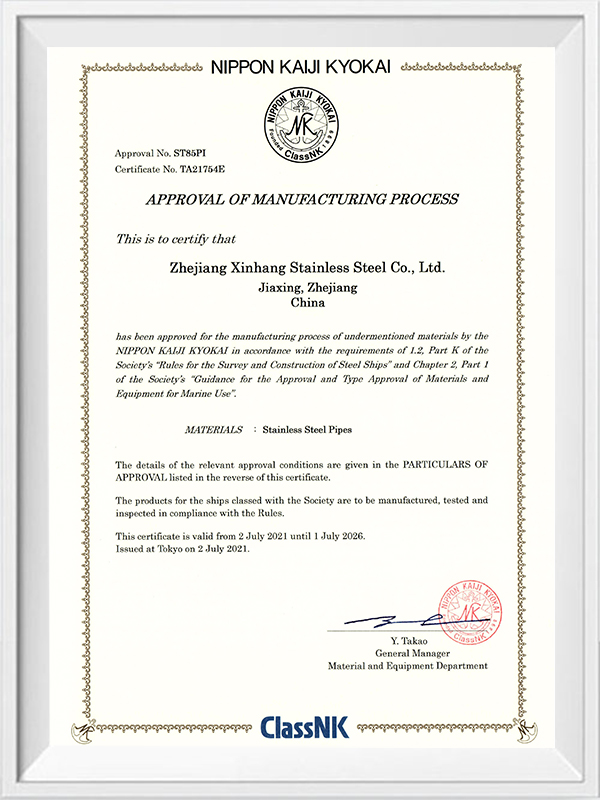

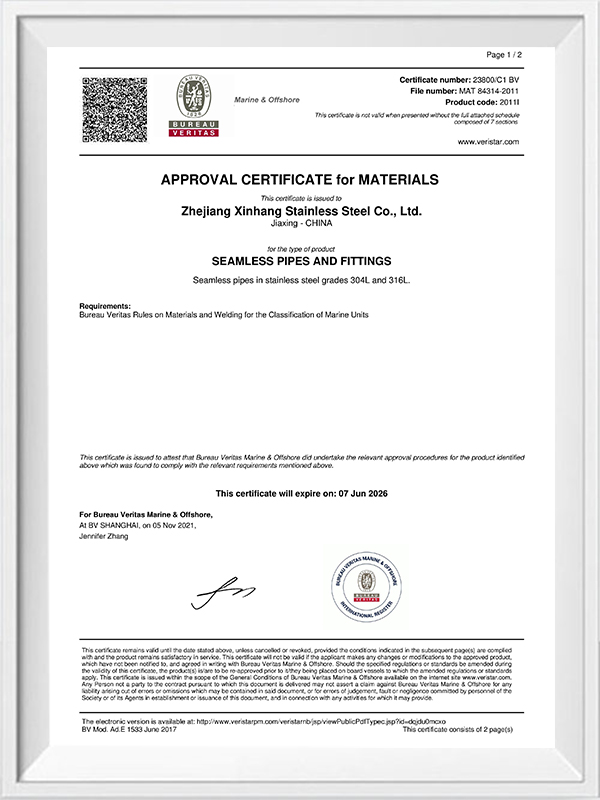

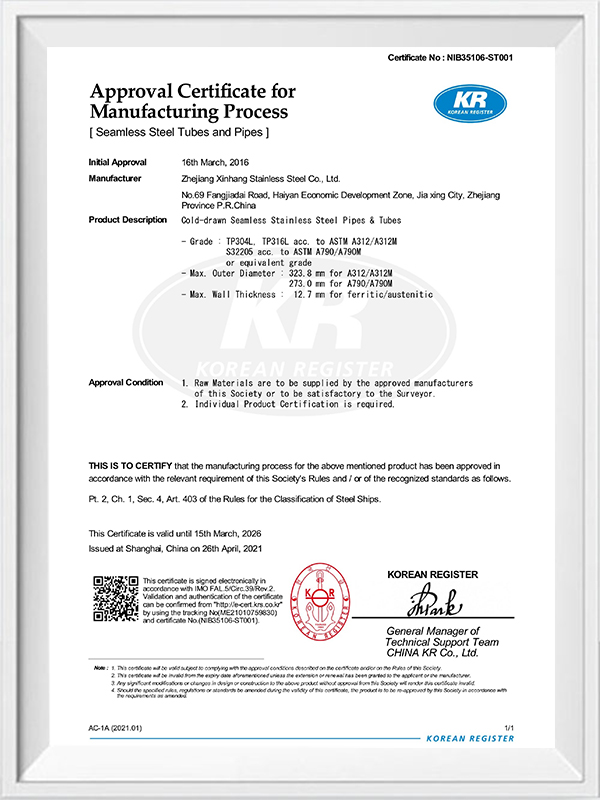

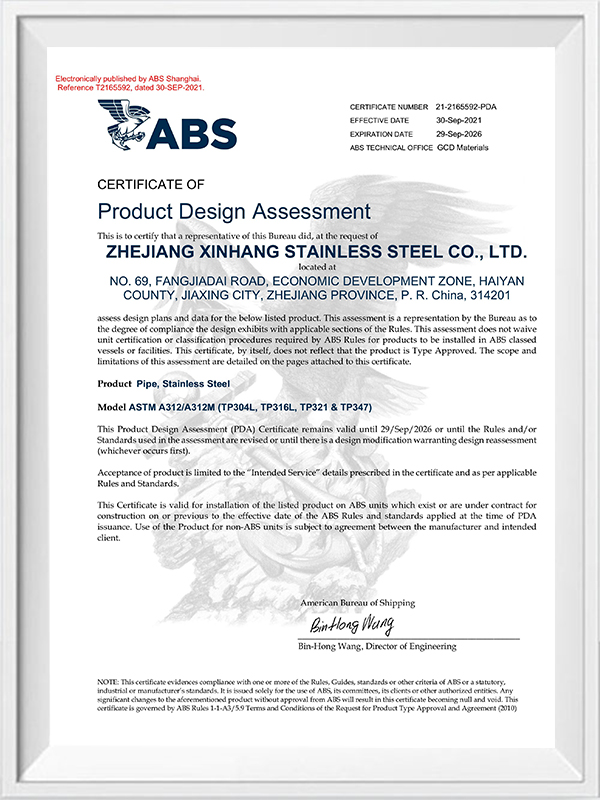

It has passed ISO9001:2008 quality management system, PED 97/23/EC EU Pressure Equipment Directive certification, China Special Equipment Manufacturing License (Pressure Tube) TS certification, ASME certification, provincial enterprise standardization management system, ISO14000:2004 environment management system, cleaner production (green enterprise), and a series of certifications, as well as China Classification Society (CCS), American Bureau of Shipping (ABS), British Register of Shipping (LR), Deutsche Veritas (GL), Bureau Veritas Society (BV), Det Norske Veritas (DNV), and Korean Register of Shipping (KR) factory certification.

The main products include stainless steel pipes, pipe fittings, flanges, valves, etc., which are widely used in petroleum, chemical industry, nuclear industry, smelting, shipbuilding, pharmaceuticals, food, water conservancy, electric power, new energy, mechanical equipment, and other fields. The company adheres to the corporate tenet of "quality for survival, reputation for development" and wholeheartedly serves every customer to create a win-win situation.

Essential Setup for TIG Welding Stainless Steel Pipe TIG welding stainless steel pipe is unforgiving of contamination and excess heat. A repeatable setup starts with stable power delivery, consistent...

View More“Corten” is a common market name for weathering steel—low-alloy structural steels engineered to form a protective oxide “patina” in the right exposure conditions. This article focuses on corten steel ...

View MoreIntroduction to Alloy Steel Alloy steel is a type of steel that is made by combining carbon steel with various alloying elements such as chromium, nickel, molybdenum, and vanadium. These alloying elem...

View MoreWe'll never share your email address and you

can opt out at any time, we promise.